Fast and Accurate Table Joinery

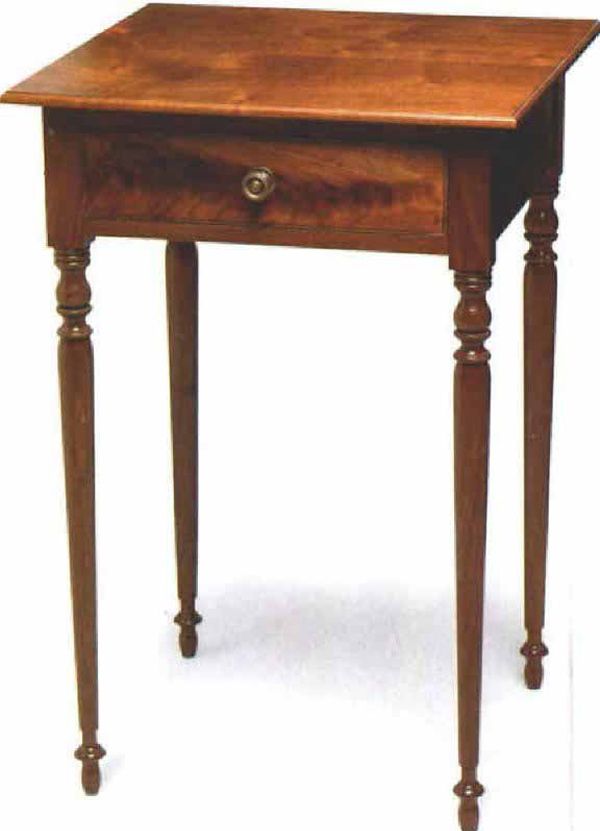

A Sheraton-style table comes together easily, thanks to an efficient approach

Synopsis: Steve Latta explains how to design a table so that it can be built with an efficient process that doesn’t sacrifice aesthetics. In this article he offers tips for planning and organizing milling tasks and for cutting accurate joinery. Included are methods for cutting mortise-and-tenon joints on the tablesaw with a shopmade jig and methods for putting together the dovetailed drawer.

When the hand, eye and brain fall in sync, something wonderful happens. I call it “hitting rhythm.” The ability to find that rhythm, however, is consciously developed over time. It begins with a combination of both instincts and careful planning that takes into consideration joinery, measurements, milling procedures and fine-tuning. If done correctly, no time is wasted remaking parts and refitting them. A piece of furniture properly planned from the start ends up precise and looks crisp.

I learned all of that the hard way. As an apprentice, I worked in a small, overcrowded shop that made a lot of dining tables. Anxious to see big slabs of outrageously figured wood, I milled the tabletops first. But days later, as the base was nearing completion, I would find the tops full of dings and scratches from being around the shop far too long. A lot of time and profit disappeared fixing those little nightmares.

Design logically, but don’t sacrifice aesthetics

There is a logical approach to building a piece. I call it “sequencing.” Well thoughtout strategies allow you to machine all of your joints (tenons, double-tusk tenons, even dovetails) at the same time, using the same initial setup, which helps ensure accuracy. In the case of this Sheraton-style table, a project built by our freshmen each year, most of the joints are executed on the tablesaw. The underlying strategies can be applied to any project, regardless of the joinery or the style.

The table consists of only a few elements: a top, four legs, three aprons, rails, a drawer and its supports. But the choices made when sizing parts can help or hinder construction. The Sheraton table is a delicate piece, so I constructed it using primarily -in.-thick stock, which makes up the top, aprons, upper and lower rails, drawer runners and kickers. The drawers are mostly -in.-thick stock, except for the -in.- thick front.

On a table like this, I design the upper and lower rails to be the same width as the leg so that they end up flush when joined. During the joinery phase it will become apparent why I like doing it this way. One big rule exists, however: Never let engineering conveniences take precedence over aesthetic concerns.

From Fine Woodworking #148

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Pfiel Chip Carving Knife

Sketchup Class

Log in or create an account to post a comment.

Sign up Log in