Beech: A Tough Nut Worth Cracking

One of the most unruly of woods is also among the most useful

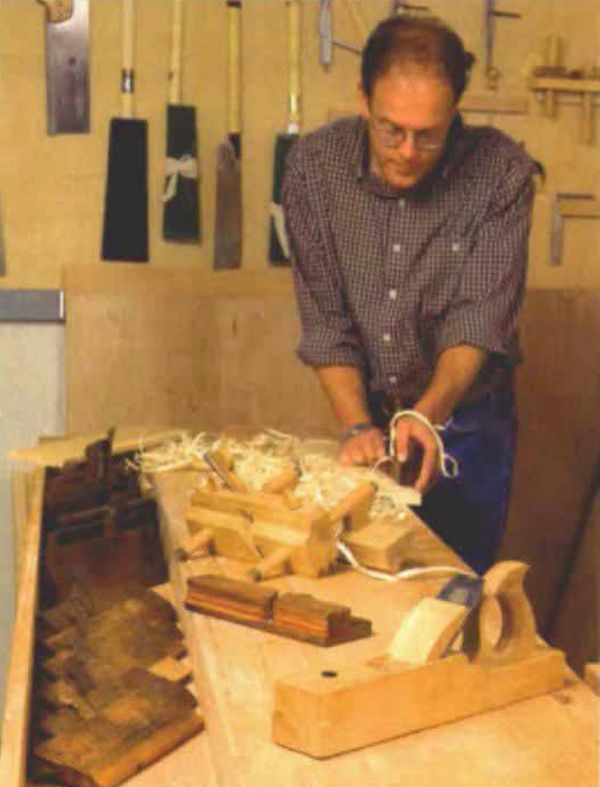

Synopsis: Jon Arno explains how to tap beech’s enticing qualities while avoiding its shortcomings. He details its best uses, such as turning stock, glue blocks, tool handles, knobs, and small essentials such as clothespins, kitchen utensils, and scrub brushes. It was ingeniously used in early Windsor chairs, because it’s excellent for bentwood parts. Arno advises that it’s best used in small parts, to manage the movement. He discusses its bio history – which woods are related to beech, where it grows, and its availability, and he closes by warning off attempts to harvest and dry it at home.

The joy of working with beech lies in the game the wood presents—the tantalizing challenge of how to tap its enticing qualities while avoiding its devastating shortcomings.

Beech’s assets are many. Close grained, it machines and turns well with minimal tearout, and it takes finish beautifully. Its hardness and ability to absorb shock make it the wood of choice for many workbenches, tool handles and mallets. Perhaps beech’s greatest attribute is the ease with which it can be steam-bent. Beech has astonishing plasticity when exposed to heat and moisture. Once steamed, it will conform to jigs that demand surprisingly tight bends without failing, and once dry, it experiences relatively little rebound.

But then there is the evil side of beech: It is extremely unstable. An average plank of beech can shrink 17.2% on its way from green to oven dry, one of the highest rates of shrinkage among domestic hardwoods. Beech’s tendency to swell and shrink with changes in humidity is nastily compounded by the enormous differential between the wood’s radial and tangential shrinkage. This differential makes beech one of the most difficult woods to season without warping and to keep flat once it is dry. Most other woods with comparable shrinkage factors are rendered useless by their propensity to check and split. Fortunately, beech is spared this fate by its abundant medullary rays, which tend to hold it together. One final frailty of beech is its poor durability when exposed to the elements.

Best uses of beech

Beech is a high-contrast species—one with a great gulf between its outstanding virtues as one of our most workable woods and its horrendous shortcomings in terms of stability and durability.

Beech’s deficiencies haven’t kept it from attaining a place among the most useful of woods. And we can learn how best to employ beech by studying how it has been used by woodworkers of the past.

In period furniture, beech is seldom seen as the primary wood in tables or case goods, where its lack of stability would be devastating. And in exterior applications, either it was seldom used or has not survived. However, it is found in abundance as turning stock, as glue blocks in the framing of upholstered furniture and as bentwood parts in chairs, where it is excellent both for steam-bending and bent lamination. Thomas Chippendale, although addicted to mahogany in fashioning the rococo style of furniture for which we know him best, used beech in special applications, for fretwork panels in his Oriental styles and as core stock for primitive “plywood” slats, where resistance to splitting was a key feature.

From Fine Woodworking #134

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid R4331 Planer

AnchorSeal Log and Lumber End-Grain Sealer

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in