Preparing a Scraper

It's just a flat piece of steel, but what a surface it leaves

Synopsis: If you’re using a well-prepared, thin scraper, you can get a surface as fine as you’d get from 400-grit paper – smooth, satiny, lustrous. Furnituremaker and sawyer Monroe Robinson talks about what you’re aiming for when you prepare a scraper, and then he shows and explains how to do it. You flatten the sides, file the edge flat and square, and then hone the edge. Then you hone the faces and burnish the edge slightly. Robinson shows you what to do with a dull scraper and offers scraping tips, too.

Many woodworkers think of scrapers as crude tools, good for little more than removing dried glue. Even those who use a scraper for surface preparation may think of scraping as an intermediate step between planing and sanding. And with the advice woodworkers are given, it’s no wonder. I once read, for instance, that after scraping a surface, you could start sanding with 80-grit paper. Why bother? The truth is that if you’re using a well-prepared, thin scraper, you can take off wispy shavings and get a surface as fine as you’d get from 400-grit papersmooth, satiny, lustrous.

Planing figured woods and many hard, exotic species almost always is a frustrating experience. One time, I made a 12-ftlong table with a surface of bandsawn Macassar ebony veneers. The little grain swirls that make the table’s surface so interesting could not have been planed without some devastating tearout. Flattening and smoothing that surface with a scraper gave me a flawless surface with no tearout.

I started with a thicker scraper, which removes a lot of wood in a hurry. I scraped the whole table down, right off the bandsaw, in about as much time as it would have taken me to plane it. I filled several 30-gal. garbage cans with the shavings from that project. Then I followed with a thinner, conventional scraper, leaving a surface that was ready to finish. But this kind of performance is only possible with a scraper that’s been properly prepared.

A well-prepared scraper

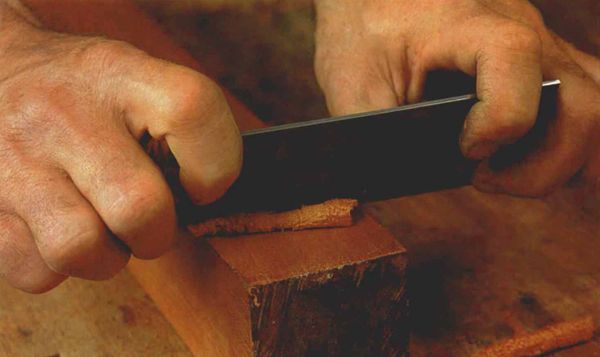

What you’re trying to achieve when you prepare a scraper are four perfectly honed 90° edges. The edges are rolled over with a burnisher just enough to create a slight burr. This burr works like a miniature plane, cutting the wood fibers cleanly—creating shavings, not dust. A well-prepared scraper works for hours and will take a dozen or more new burrs before it must be rehoned. The photos and drawings on these two pages explain how to prepare a scraper in detail. It takes me about 10 minutes to prepare a new scraper. Re-honing an old one takes five minutes or so.

If the scraper’s edge (or the in. or so on either side of the edge) isn’t perfectly polished, you won’t be able to burnish the scraper more than a couple of times before having to take it back to the stones. Even the smallest scratches and nicks will yield an edge that, on a microscopic level, is ragged and weak.

From Fine Woodworking #114

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Tite-Mark Marking Gauge

Rockler Silicone Sharpening Stone Tray

Log in or create an account to post a comment.

Sign up Log in