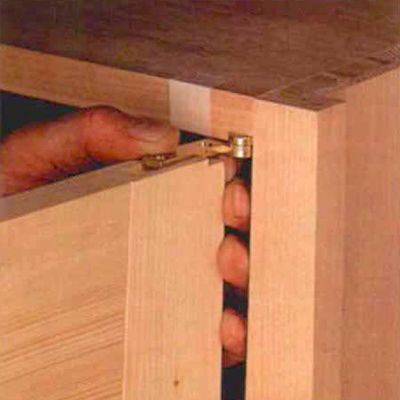

Installing Knife Hinges

Careful layout and mortising are keys to success

Synopsis: Knife hinges have a simple, subtle beauty, writes Gary Rogowski. Don’t buy inexpensive hinges; he includes a list of things to avoid, such as stamped steel and riveted pins. Accurate placement is key, and he shows how to lay out the setting. He explains how to get the doors to fit snugly and how to correct your mistakes if things aren’t just perfect.

Knife hinges are a sweet finale to a piece of cabinetry. They have a simple, subtle beauty. Just a small semicircle of brass is all that shows with the door closed, letting the lines of the furniture and the figure of the wood take center stage. Knife hinges also are tremendously strong and almost totally resistant to sagging, making them the hinges of choice wherever a narrow, consistent reveal around a door is important.

Knife hinges are strong because of the orientation of their leaves. Their leaves are mortised flush to the horizontal surfaces of the door and the carcase. The forces of gravity and leverage acting on the hinge put shearing forces on the screws. In other words, for the door to fall off its hinges, or even sag, the screws would have to shear, or the door frame or the carcase would have to be destroyed. Not so with butt hinges, where gravity and leverage exert forces of tension on the screws. Over time, this causes the door to sag and tends to pull the screws out of their holes.

Despite their advantages, knife hinges have gotten a bad rap for being notoriously difficult to install. They are less forgiving of sloppiness, but with a little extra care in layout and mortising, knife hinges are no more difficult to install than butt hinges.

Don’t buy inexpensive hinges

A number of different types and brands of knife hinges are available, but only one brand I know if is really worth considering. Avoid hinges that are made from stamped steel, have riveted pins (making them inseparable and, therefore, next to impossible to install accurately) or are finished poorly. The good ones are made by Larry and Faye Brusso and are available through many woodworking catalogs or directly from Larry and Faye Brusso Co. Inc.

Brusso hinges consist of two machined and polished brass leaves, each about 1/8 in. thick, countersunk for screws. The leaves, which come apart, pivot on a short pin and are separated by a single washer.

From Fine Woodworking #111

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Bessey K-Body Parallel-Jaw Clamp

Dubuque Clamp Works Bar Clamps - 4 pack

Log in or create an account to post a comment.

Sign up Log in