Synopsis: For those woodworkers intent on a more developed level of workmanship, the hand plane still has an assured place in the shop. It is unique in its ability to deliver a smooth, clear surface unattainable in any other manner. Here, Ian J. Kirby explains the various types and parts of modern wooden and metal planes, how to select and adjust them, and how to use them. Three common bench planes are sold today, and he talks about how they are made and how to adjust them. In using them, the proper grip and stance are essential, and Kirby demonstrates both as well as explaining them. Side information covers tuning up planes.

In woodworking, there is no sound quite as delightful as the clear hiss of a sharp plane taking off a thin shaving. Nor can any other tool so precisely remove a modicum of wood tissue while leaving a perfectly flat and smooth surface. Of the three basic woodworking tools—saw, plane and chisel— the plane alone projects such a false sense of complexity that much modern woodworking is done without it. To be sure, many of its operations can now be done faster by machine. Where the cabinetmaker once had bench, plow and molding planes, he now has power jointer, router and spindle shaper.

For those woodworkers intent on a more developed level of workmanship, however, the hand plane still has an assured place in the shop. No machine, no matter how cleverly contrived, can match the plane’s virtuosity in fitting drawers and doors, aligning twisted frame assemblies or leveling surfaces. The plane is unique in its ability to deliver a smooth, clear surface unattainable in any other manner.

Woodworkers of yesterday had dozens of planes to pick from. Though many are still available today, you need to own only one or two to perform most planing work.

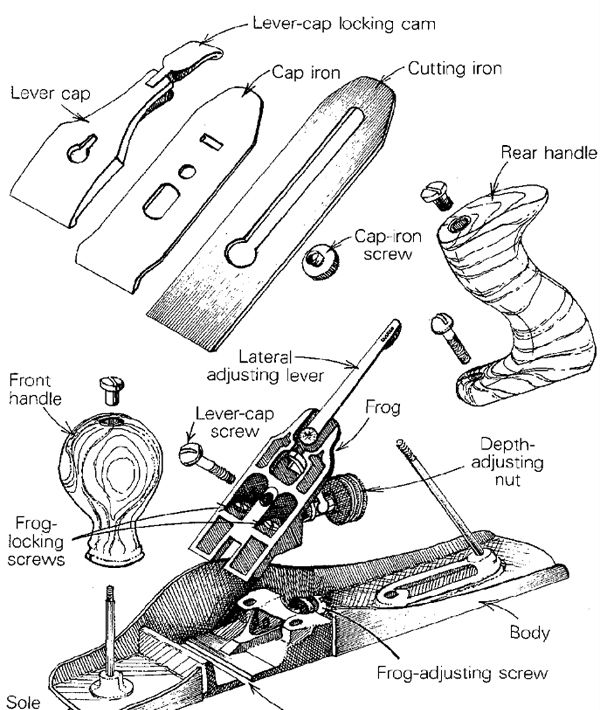

In this article, I’ll explain the various types and parts of modern metal planes, how to select and adjust them and, most important, how to use them. These principles apply to wooden planes also.

Why planes?—The woodworker’s plane has been around for centuries. Unearthed tomb paintings depict Egyptian carpenters using planes to square up timbers. This remarkable history stems from the plane’s basic usefulness; except for the adze and drawknife, no other primitive tool can prepare cleft or roughsawn wood to final dimensions. In its basic function and form, the plane has changed little: all planes consist of a blade or iron firmly mounted on a bed in the body of the tool. The blade must be adjustable and easily removable for sharpening. The bottom, or sole, of the plane must be kept flat and out of winding. The whole assembly, blade and body, must accommodate the hands or have handles so the operator can control the tool.

From Fine Woodworking #35

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Veritas Precision Square

Log in or create an account to post a comment.

Sign up Log in