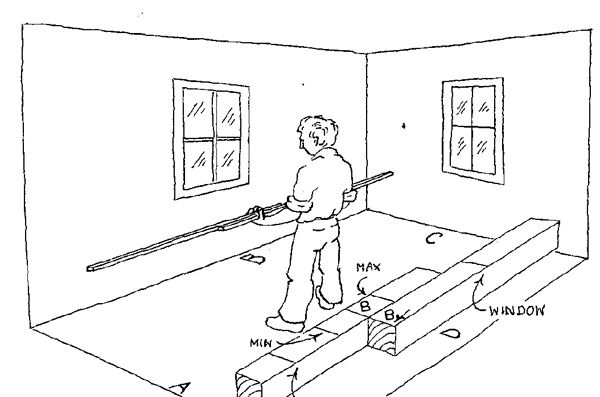

Synopsis: Prior to the introduction of S-curves in the late 17th century and the multiple-angle joinery of the Chippendale period, most furniture was joined very simply and readily adaptable to stick layout, writes Hank Gilpin. The introduction of complex joinery and curved forms in furniture has not diminished this method’s usefulness. Stick layout can take the place of full-scale drawings, and Gilpin explains how to do it. In this detailed article, he shows how to build cabinets into a room using only two sticks to measure the room and all its permanent elements.

The stick method of measuring and drawing is by no means new. I’m certain it predates all other methods used in designing furniture, since the availability of large pieces of paper is a relatively recent luxury. Prior to the introduction of S-curves in the late 17th century and the multiple-angle joinery of the Chippendale period, most furniture was joined very simply and readily adaptable to stick layout. The introduction of complex joinery and curved forms in furniture has not diminished this method’s usefulness because even today most wooden objects are based on rectangles and squares. Contemporary English cabinetmakers use this method for nearly all construction except chairs, which are difficult to lay out on a stick. However, the simple Carver chairs of colonial America and the delicate chairs turned by the Shakers are obvious results of the stick method. In reproduction work the stick is very handy. If you are asked to duplicate a Sheraton bow-front chest, all you have to do is hold a stick to the front and scribe all the elements of the chest onto the sticks. Then you need only a full-scale drawing of the front curve.

I was introduced to the stick method by Tage Frid during the construction of a library circulation desk that measured 15 ft. by 18 ft. Frid grabbed the scale floor plan we’d drawn up, took a few measurements and covered two sticks with mysterious pencil lines. He made a cutting list, somehow related to those marks on the stick, attacked a 24-sheet pile of plywood, cutting, grooving and tonguing and in less time than it would have taken to execute a full-scale drawing (I’d still be hunting for an 18-ft. table) all the parts for the desk were cut to size tongued and grooved, and ready to be glued together.

None of this really sank in until I had my own shop and was faced with my first big job. But, once I had adapted to the sticks as a substitute for full-scale drawings and devised my own method of marking, I wondered how I ever worked without them. Every element of a job can be drawn on just two sticks: doors, drawers, carcases and frames, drawer sides, bottoms, pulls, hinges, edge-banding and shelves.

From Fine Woodworking #6

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Circle Guide

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in