Roubo Bench with Hand made wooden Wagon-vise

The Roubo style bench with 4 inch top is made of local Virginia ash and has a vise with a purchased wooden screw and a wagon vise with a shop turned wooden screw. The other modification to the standard design is a bench stop at the opositwe end and a fancy wooden escutchen made of walnut. With 5 inch legs this bench is solid during all planing operations. Wooden Screws apply more presure than you would ever need in wood working while adding an “Old World” flavor to the project

Comments

Do you have any details you can share on how you made your "shop turned wooden screw" and tail vise? Wonderful execution of the Roubo.

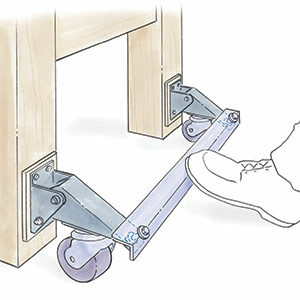

Sorry no plan, designed it as I went along. Rout two 3/4 inch groves in the bench before gluing the top together. The block has two 3/4 inch splines to allow the block to move nicely in the groves. I turned the screw in my lathe out of glued up maple creating a dowel of 1 1/2 inches in thickness with the butt end 3 1/2 inches to match the purchased screw I used in the vise. . I suppose you could rig a purchased dowel if you chose. I then purchased a 1 1/2 inch screw cutter available at several places online and threaded the rod portion. You can see in the picture that the block is attached to the screw rod by a 1/2 inch maple plate with a lag bolt through the plate into the rod. The plate is then secured to the block with two screws. It is really strong and hasn't been a problem with either pushing or pulling. Of course there are two 3/4 inch holes which accept veritas "brass dogs".

Nice bench! Mine bench has wood screws too. I bought them from Howard Card at Crystal Creek Millworks years ago. He made the pair out of 16/4 hickory and they perform beautifully. I rubbed a little homemade beeswax blend on the threads and you can spin the handle. I wish I could get another pair but he's no longer making them.

Again, nice bench, bro.

always,

Zee

You can get a complete lesson in how to make wooden bench vise screw threads on youtube by asking for Mrcartersaccount - he has a number of videos on how this is done - and it works! I am in the process of making a Roubo type bench and I decided to make the screw threads before going on with the bench - so now the bench will go ahead.

Log in or create an account to post a comment.

Sign up Log in