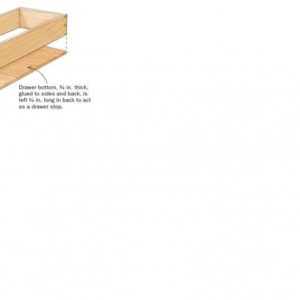

In Steve Latta’s Spice Box (FWW 196 Jan/Feb 2008 Pg 61 http://www.taunton.com/finewoodworking/FWNPDF/011196058.pdf ) he suggests that the drawer bottoms be glued to the sides and back of the drawers. See attached detail of the drawer.

Some of the drawers are 13″ X 9″ in size and I am wondering if the wood movement will cause the base or sides to crack. Of course, Steve Latta knows what he is doing but I would like to clarify this to improve my understanding of this subject, and make sure the drawers I am making do not crack open.

Would appeciate any advice.

Thanks,

Sanjeev

Edited 11/1/2008 12:14 pm ET by Sanjeev

Edited 11/1/2008 12:21 pm ET by Sanjeev

Replies

S,

The bottom will expand/contract differentially to the sides, as you note. But it's the degree of moisture changes in the air, taken up by the wood, that will determine how much this becomes a problem and whether it will lead to cracking or other problems.

Although I always make stuff to take account of possible expansion & contraction, the fact is that the atmosphere in most modern British houses is fairly constant, humdity-wise. Sometimes there may be a dry conservatory (too much sun) or a relatively damp room (eg a cellar) but these are exceptions.

But I understand that humidity levels change much more with the seasons in various parts of the USA.

In all events, should there be a largish differential contraction in that drawer, the bottom would crack across its grain. It would be very unlikely that the sides be affected as the force would be along their grain. I suppose they might take on a twist or other jamb-making shape.

If the drawer corners are DT they will mechanically resist the corners breaking if there is expansion. What would break instead? I don't know. Finger or other joints relying only on glue might part, if there is expansion.

I have seen old drawers in which the bottom panel has got stuck in its groove then cracked by differential expansion. You also see quite a bit of this in old furniture with frame and panel, where the panel was stuck in the frame rather than left floating. The panel cracks along the grain (contraction) or the M&T frame joints open up (expansion).

I'd give that drawer you picture a floating bum; or use a nicely veneered thin plywood, if gluing-on of the bottom is needed for strength.

Lataxe

Sanjeev,

I agree with you, I'd be concerned. That drawer bottom could easily expand 1/4" or more unless its plywood. I would glue in the panel in the front, only and maybe the first inch or two on the sides, and let the rest float.

From the drawing it doesnt look like these get slid into a groove in the sides or the front either. So the only way the bottom is held on is by gluing onto the bottom edges of the sides and back. Looks like the sides are higher at the bottom to allow the bottom panel to fit without extending beneath the drawer front. So if you didn't attach it according to the plans, would you revise them for a floating panel?

The glued joint at the back/bottom is the one that seems questionable to me, but maybe the reason he's able to get away with it is the thinness (1/4") of the back and bottom maybe not moving so much as something thicker??

If you build it he will come.

Sanjeev,

This construction is a traditional method. Often, however, it results in either failed glue joints, or cracked bottoms. Using quartersawn (edgegrain) stock for the bottom will reduce the amount of movement, and the probability of failures.

Alternative construction methods I've seen in old work are:

1) bevelled edges on the bottom, let into 1/8" grooves in front and sides. This is by far the most common method.

2)angled ends on the drawer's bottom, making the bottom in effect a sliding dovetail. This slips into matching angled grooves in the drawer sides. Glued along the front, the projecting edge of the bottom advances and recedes with seasonal movement. Note that drawer bottom grain direction ought always to be from side to side; if the grain runs front to back, shrinkage will allow the bottom to drop from its groove. This technique I've seen on desk interior drawers in period pieces in Connecticut and Virginia, but it is not common.

Ray

In D. Douglas Mooberry's article

http://www.taunton.com/finewoodworking/ProjectsAndDesign/ProjectsAndDesignPDF.aspx?id=2466

He says:

Because the box is so small, I don't worry

about cross-grain construction.

This construction works well

for very small drawers only. On anything

larger, wood movement would cause them

to come apart.

Larry Crossan in Woodshop news Oct 2001 uses the same construction. It must be a recognized standard for this spice cabinet to glue bottoms on in this way.

Larry was a restorer , hopefully saw a few of these original, so it seems if there is a problem with this design he would not use it in his own work.

These spice boxes have fascinated me since I first saw one. I have been collecting articles about these and so my reason for tossing in my two cents here. Definitely on my list to make some of these.

Thanks for pointing this out. I guess I took for granted they just put the bottom in grove and I did not notice this stick it on the bottom of the sides method.

Lonnie Bird's 18th-century Pennsylvania secretary has drawer bottoms for even the smallest hidden drawers slid into grooves in the sides in the conventional manner.

Might be worth a call to the Smithsonian or other keeper of our national treasures to find out how the original spice cabinets have faired over the years.

If nothing else maybe it is plywood time.

Edited 11/2/2008 1:50 am by roc

Edited 11/2/2008 1:54 am by roc

I've not seen much 18th c furniture where drawer bottoms were in grooves. I can't think of a piece off the top of my head. Glued and nail up drawers are common and typical of Philadelphia furniture. Drawer bottom grain (on Philadelphia pieces) usually runs front to back, not side to side, tho there are a few exceptions.

Very very few drawer bottoms are cracked. A closer examination reveals that the drawer bottoms, indeed the drawer sides as well, are always quartersawn. Even closer examination of a greater number of pieces reveals that the stock is actually not quartersawn but riven. In either case, expansion and contraction of these pieces is primarily through there thickness, not width.

Adam

Edited 11/2/2008 6:53 am ET by AdamCherubini

No expert on wood expansion. That said..

I have made many spice and jewelry boxes over the years. None made with plywood. (I have nothing against plywood)... For 'small' boxes I usually glue the drawer bottom at the center of each side and center of the front and back. No exact dimension for the area of glue coverage. Maybe 1/2 inch or so and no glue for the remaining.

Just so you know, I always resaw my wood for the majority of the drawer parts so I can get at least get close to Quarter Sawn... If I cannot get QS I will get some Riff cut and resaw that for parts. Drawer fronts I just pick for grain.

As a suggestion for you to try. For the past few years I have been using the method shown on page 63 of your link for the drawer bottoms. Maybe your link is where I got the idea from. Not sure. I love my router tables and the V bit will cut the V slots and the V for the drawer bottom. You can get a really nice fit if you plan ahead and I now use no glue.

As the Spice Box maker did with the partition panels, I do for the drawer bottoms. I get a really nice fit and I do not use glue. But then again, if I think about it, with a 'nice tight fit' and no glue... If the bottom expands something has to give anyway! Glue or NOT!

Edited 11/2/2008 11:50 am by WillGeorge

This forum post is now archived. Commenting has been disabled