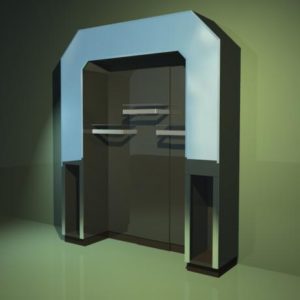

I am making 4 identical, huge cabinets for a fancy shop. Each cabinet is made up of 4 components: 2 vertical cabinets, a top cabinet and a large back panel connecting the two side cabinets. The best way to picture it is to think of Stonehenge with a back panel. The size (and weight) of the unit is considerable; from ground to top of top unit is c 9ft and total width is about 7ft, but they are quite shallow c 18 inches. I’ve attached an image to be clearer – Anyway – here is the problem – I can assemble them relatively easily in the workshop and could do the same on site but to complete them I have to access the back of the units. When finally installed they need to be close to the wall so I have to effectively complete them at least my thickness (!) away from the wall.

What is the best way to move them back that final 3 ft? I am concerned about shimmying them into position because of racking etc. I can’t put trolley jacks underneath them because there is not enough clearance underneath (c 3 1/2 in). Oh and here’s the best bit – I can’t guarantee that I will have help during the installation. (the fronts are all mirrored but these can all be fitted after .)

Any advice gratefully received!!

Replies

Get some of the furniture "slider" stuff at HD or Walmart. It comes fairly thin. Just install that on the bottom and leave it there. And, make a false front that spans the width of the total cabinet and screw it on to the unit at points where the later installation of the mirrors will hide the screw holes when you take off the false front.

Oh, by the way, it looks great!

-Bob

Push it back 1 inch at a time from each side the racking should not be a problem. Is the floor carpeted? Better would be to lay down a large piece of plexyglass to make it easier to slide the unit then use a 2x4 stud across the two towers and push both at the same time. Next time try to design it to be modular. I built two pieces that were large and unwieldly as one piece. Both instalations were horrible. Now I always build large parts to be knocked down into smaller boxes.

Hope that helps,

Mike

I like the idea of sliders suggested earlier. I'm pretty sure I have seen them in the Rockler catalog, and as suggested you could install them in the bottoms of your cabinets, slide the unit into place, and just leave them in.

The plexiglass could work; but have you thought of the old trick of laying down pipes under the piece before you assemble it , and then rolling it across the pipes to move it against the wall? If the floor is hardsurfaced, you could wrap the pipes with duct tape so they won't scratch the floor.

Beautiful piece!!! Must be going into a retail store of some kind?

I was thinking of a few bits of 1/2", 3/4"or 1"diameter dowel laid on the floor roughly parallel with the back wall. Slainte.RJFurniture

Thanks for the advice (and compliments).

I forgot to add one (critical?) point - that the cabinets themselves are on 3 1/2" adjustable legs covered by a plinth.

I had thought of putting castors inside the area where the feet were and then rolling them back, cranking the legs down when in place but I think that all the wheels will be too close together to be stable and also I'm not sure what I can use to take the weight off the threads on the adjustable legs when I'm winding them up.

Mike I totally agree with you about the modular construction but I think they are in as few bits as possible given the way the mirroring works and it still all has to be tied together before it can be moved because of wiring etc.

Definitely one of those commissions where lots of 'learning' happens

Oh by the way, the floor is terracotta tiles which are slightly uneven!! I'll post pics if they ever get installed properly!!

Cheers

Wow! You've got problems upon problems!

How about laying strips of formica on the tile, extending all the way back to the wall, spanced so that the legs fall on top of them. Then, when the unit is assembled and ready to be pushed back, the legs should slide on the formica. With the unit against the wall, use a lever to lift up the unit by a small amount and pull out the formica strips. But you still need some type of false front to take care of the twisting problem.

-Bob

Could you put swivel casters under the cabinet with the adjustable legs?

If so, leave the adjustments fully retracted and roll the cabinet into place then jack it up and level it with the adjustable legs. This would make installation a one person job and allow easy future loves. (Retract the legs and roll it away.)

I did something similar with an entertainment center for a 200# TV. It doesn't have legs, but it's on casters with a molding that clears the floor by ~1/2". It would have been a simple matter to have added adjustable leveling legs if required.

Just a thought.

Well they are finally in! Have attached a couple of photos - clients are happy (and have paid!!) Thank you for your advice and help. I decided on putting castors on the side cabinets which really helped moving them large distances but the really useful bit of kit in the end was my Father in law!!

Hope you like them

Hi Tim,

I remember your last post when you wanted advice on moving those cabinents. It didn't occur to me at the time I posted my opinion, but have you thought about an air-sled. It basically uses air from a shop vac to lift appliances of the floor and floats them on a column of air!

Here is the website, but be forewarned the prices for an air-sled start at $500 and spiral upwards!: http://www.airsled.com

Those daring young men in their flying machines!

Great idea but I have to say there are a lot of other things I need to spend my 'hard- earned' on first. Thanks for the thought though.

T

Tim, you didn't mention the type of floor covering that the unit will be installed on. If it's hardwood or some other flooring besides carpet, you can slide it in on pieces of scrap formica.If you are concerned about racking, make a rectangular frame out of 2x4's padded, clamp the bottom cabinets with this as a spacer. This will keep it rigid while you slide it back.

mike

Tim, I dont' have anything better to suggest, but you have to tell me what you used to render that image with.

I have to confess that I don't do the rendering. A friend of mine does it (for the love of it) usng a seriously high end program (c£5k) and it takes him hours and hours and hours. I can't tell you how much it helps clarify things in customers' minds. I only ask him to do it on unusual or complicated, difficult to visualise jobs. When I next speak to him I'll ask and let you know.

T

Tim, have you thought of using lifting straps like the appliance delivery guys use! It's simply a long canvas strap that goes under an appliance like a refrigerator, and the ends have loops so they can be grabbed on each side, and the appliance is then lifted and slowly moved. I read you can't guarantee help, but in this case you will need someone on the other side of the strap. I took a look at the photo, excellent job, well done!

Those daring young men in their flying machines!

I hadn't thought about putting framing across the front to prevent racking - good idea - so is the formica.

Thanks for the help - anymore gratefully received.

Cheers

T

Tim

some good ideas here, but everyone apperas to have assumed that the floor on which the cabines will rest is perfect.

It's more likely that you will need to construct a separate base that you will place on the floor in the final location, level and then move the cabinets onto. You said there were four? I'm assuming that to the eye the client will want the tops to all be at the same height – with an uneven floor this will mean four different bases. Make a fifth base, use this as a platform on which to build the cabinet itself and then slide it off onto the permanent base.

Ian

This forum post is now archived. Commenting has been disabled