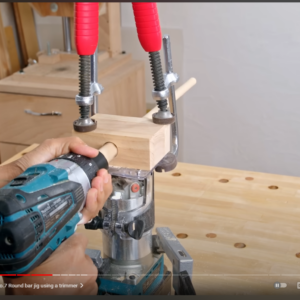

I’m about to make this little jig, as it seems like a very quick and easy way to make some dowels I’ll need soon. I’ve usually just bought them, but the tolerances have been all over the place with Woodcraft stuff, at least.

https://www.youtube.com/watch?v=eYOEbS_ACY0

Skip to 9:44

Is there a better or alternative way to make them?

Are there obvious problems I’m not seeing with this?

Do you guys generally use something else instead of dowels in the first place?

Replies

What are you using the dowels for?

Doweling template on Amazon ..

Floating tenons

Ordered. Thank you. the janky router thing didnt work very well....idk why i thought it would..

+1 on the that dowel plate. If hammering through I’ve found that a little paraffin wax on the 1st 3rd of the stock really helps drive it through and reduces tear out.

Thats a great tip. Thanks

“[Deleted]”

There's a lot of dowel-making methods around, some quite effective and others .... not. There's a number of things you need to consider before making any dowels yourself, which will affect the choice of method that will give the quality of results that you want.

So......

* What are you using the dowels for?

* Will they show or be buried in the work (is colour/timber-type matching needed, for example)?

* Are they primarily for alignment, joint-strengthening or both?

* How long do they need to be?

* What diameters do you need?

* What stock have you got for making them (straight grain is essential)?

Personally I use a good quality commercially-sold dowel for no-show dowelling. There are sources (in the UK at least) for accurately-sized dowels of straight grain, typically beech. Other sources for high quality dowels made of various timbers are available, usually sold in one meter lengths rather than as packets of shorter dowel.

Here's a British website that sells oodles of dowels:

https://www.toolsandtimber.co.uk/catalogsearch/result/index/?p=4&q=dowels

For show-dowels I make my own from appropriate species of scrap on the drill press with a set of dowel-cutting bits. Many of these bits cost a lot but are very accurate and effective. Some are cheap but don't produce very clean-cut or accurate results. There are medium-cost bits to be found that can be sharpened to a better effectiveness and that's what I have. A set of 6,8,10 and 12mm diameter bits that'll cut dowels up to 75mm long.

Bashing a piece of oversized wood through a dowel plate can work but the dowel plate edges need to be true, sharp and hard; the wood pieces bashed through need to be very straight-grained and sized just right to go through without tearing off lumps or leaving parts too thin to get rounded properly.

At bottom, you get what you pay for with dowel-making tooling. Even with the best, you need to pay a lot of attention to the nature and quality of the wood being turned into dowels. You also need to get the process just right. It does need a degree of understanding and skill to make the process, whatever it is, work properly.

Lataxe

As always, an incredibly informative reply. Thank you!

Can you link your favorite bit/s?

I'd like to purchase these as well and would totally trust your reccomendation.

Hi Ben,

Being British, I tend to buy from British retailers. (This avoids all sorts of customs duty and postage issues). So, I can only recommend those I've bought and used from Axminster, a UK retailer of many woodworking things.

This webpage shows the Axminter own-brand dowel cutters I use as well as the probably better but much more expensive Fisch cutters.

https://www.axminstertools.com/instantsearch/result?q=dowel%20cutter

The set of (plus a couple of individual) cutters I bought are the Axminster own-brand, which are likely made somewhere in the Far East. They're accurately sized but needed to be honed with a fine-grit 3M paper to make them cut as cleanly as I want the dowels to be.

You also need a good drill press with significant power but insignificant run-out to use them in; and that straight-grained scrap to cut dowels out of. I use a Nova Voyager, the power and accuracy of which may help mediocre bits perform at their best.

The Fisch dowel cutters get good reviews but they're bluddy expensive! I've not used one myself.

***********

I find that I can make around 4 good quality dowels out of 5 attempts. There's always one dowel out of any lump of scrap that ends up with a bit of rag, tear-out or some other fault. The longer your attempted dowel, the more chance of such tear-out.

It's best to go slow (rotation & plunge) and steady when cutting .... but not so slow and steady that the bit gets too hot. One drill pressing per dowel is best but with the longer/bigger ones you may have to take the bit out of the scrap periodically to let the bit cool.

Cut with the grain, obviously! :-)

I used to use a lot of walnut and cherry dowels so I made one similar years ago that clamped to my router table. It had a half dozen hole sizes so I could make various dowels. It does take a bit of setup and testing to get the router bit set to the proper height but once done the dowels came out smooth and polished. Also, the square stock had to be exact to match the diameter of the input hole. Otherwise the dowels came out "threaded" and rough. Once you get your stock planed to the right size and your bit adjusted make extra for future use.

Dowels do not = floating tenons.

+1 for a dowel plate. Use mine quite a bit. Straight grain is almost a must. Work your way down to your size.