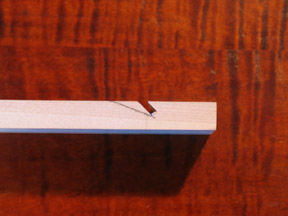

I am building a small project that has a piece of 1/8″ thick material slide into the groove cut on the tablesaw. I would like to change the angle on the groove from 45 degrees to roughly the penciled in line. Any suggestions on how to do this on the tablesaw? I think there is an easy answer that I am just not seeing. Thanks in advance for any help. Kieran

Discussion Forum

Get It All!

UNLIMITED Membership is like taking a master class in woodworking for less than $10 a month.

Start Your Free TrialCategories

Discussion Forum

Digital Plans Library

Member exclusive! – Plans for everyone – from beginners to experts – right at your fingertips.

Highlights

-

Shape Your Skills

when you sign up for our emails

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply. -

Shop Talk Live Podcast

Shop Talk Live Podcast -

Our favorite articles and videos

Our favorite articles and videos -

E-Learning Courses from Fine Woodworking

-

-

Fine Woodworking New England Event

Fine Woodworking New England Event -

Replies

I think a radial arm saw will tilt over that far.

Kieran..

The only thing I can think of is to build a jig to carry the stock at an angle;-

jig angle + blade angle = desired angle....

Mike Wallace

Stay safe....Have fun

Kieran-

The angle appears to be quite a bit past 45 degrees, which means it is beyond the ability of the table saw, if you lay it flat. However, there is an easy solution. It would help to know if you have a tenoning jig. 1st, using a bevel guage, match the angle of the line with the board perpindicular to your bench. Using the bevel guage, match the angle of the saw blade to it. Attach the stock to the tenoning jig, and run it through the saw, being careful that the blade clearance does not hit the tenoning jig. Make sure you use the jig in the miter track so the blade tilts away from the jig. If you don't have a tenoning jig, make a simple one out of mdf, creating a vertical surface perpindicular to your saw. Clamp your stock vertically to it, and using your fence to run the jig along, (as in a ripping process), cut the piece. If your stock is too long to clear the roof in your shop, wheel your saw outside, and do it there.

JC

Unfortunately, I don't own a radial arm saw or a tenoning jig. JC, If I understand your suggestions, I think it would work only if the cut was going in the opposite direction on the board. Thanks for all the input. I think I may have to try to freehand the cuts on the bandsaw.Kieran

Kieran,

The enclosed graphic should be self explanatory. The work piece is vertical, running along a higher sacrificial fence, and (the work piece) is held in place by an appropriate safety device.

If you have any questions, please feel free to ask!

Dan Kornfeld, Owner/President - Odyssey Wood Design, Inc.

Edited 11/27/2004 7:43 pm ET by Jackie Chan

Thanks Dan for the input. From your drawing, I think that method would work only if the slot opening was facing the end of the boards and not directed towards the center (as I need it to be). I was able to fashion a jig for my chop saw. Works okay, however, would have been easier if I had a sliding miter saw or radial arm saw. Thanks again for taking the time to evaluate my question.Kieran

Kieran,

If you have a safe and stable cross cut sled, or even a good miter gauge set up, on your table saw, here's an alternate option. Hot glue a piece of scrap across the width of the board to be cut. The piece needs to be the correct thickness and placed in the right location, so as to cant the board to the correct cutting angle. This may take some experimentation regarding the thickness of the scrap. To prevent tear out, you might consider placing the glued on piece right in the path of the blade. This way the scrap will be acting as backer board of sorts. Make sure the work piece is secured and controllable through the cut - safety above all.Dan Kornfeld, Owner/President - Odyssey Wood Design, Inc.

There is no way to cut that on a TS. The angle goes the wrong way. Even trying to lift the end of the board to change the angle looks imposible because the blade would have to be huge the reach. I actually was faced with the same problem in a piece I designed (figures) I ended up redesigning that detail as I have no RAS (yet) and little patience for hand tools.

That is a job for a RAS or hand saw and chisels.

Mikeplease excuse my spelling.

I don't know if you have tried to make this cut yet, but if the board is too long, it's not even possible on a table saw because the blade diameter isn't large enough. It looks like the angle is around 35 degrees. The easiest way would be on a radial arm saw with the end of the board raised to the correct angle. Check with a local lumber yard to see if they have one, since you said that you don't. Some yards just sell, some actually will cut for their customers if the order is large enough and they have the equipment.

"I cut this piece four times and it's still too short."

I agree. I described this procedure to Kieran (original poster), to be used as a last resort. You are correct regarding the length of the board - it would have to be under a certain length to provide the correct geometry to obtain the desired cutting angle. A radial arm saw would be the optimum tool for this cutting job. The motor/blade can be rotated on its x-axis to the point that the blade is parallel (a 90 degree rotation) to the saw's table. (This also allows for different tools to be mounted to the second arbor on the side of the RAS motor.) I run a old DeWalt cast iron 12" RAS that I restored, that would be a perfect tool for Kieran to use for a cut like this.Dan Kornfeld, Owner/President - Odyssey Wood Design, Inc.

I haven't tried this, but I was just thinking that a tilting base laminate trimmer with a slot cutting bit may work since the normal position of the cutter is parallel to the surface it's sitting on. If the base is tilted to whatever the correct angle is, just go slowly and use a fence to guide it along. This would only be with a base that has a flat edge to guide it along. For that matter, a dedicated biscuit cutter with the tilt feature should work because the edge that rests on the material to cause the blade to come out is flat. Just set it so the blade doesn't extend fully and be very careful.

"I cut this piece four times and it's still too short."

Bandsaw

Ron

This forum post is now archived. Commenting has been disabled