Can you use the “ruler trick” on the blade of a router plane?????

Hi:

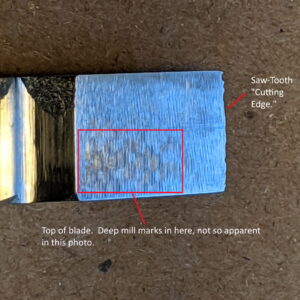

I purchased the Bench Dog router plane from Rockler (online) and the blade that came with the plane is really, really bad! I’ve asked Rockler if I can swap this blade for a good one but their site is saying that they are backed up and it will be a while before they can reply.

While I’m waiting I thought I might fool around trying to fix this blade but because the “cutting edge” (stated for reference only – you’re not cutting anything with this edge) is so bad I got to wondering if some version of the “ruler trick” might not work on this blade, avoiding having to flatten the entire back. Obviously you’d use a much thinner “ruler” on this short of a blade, but because the reference surface is still the bottom of the plane itself, it seems like a valid approach.

Replies

Put the blade in the plane to see how it presents to the wood below. If it presents with the "sole" of the blade flat to the work you'll have to flatten the whole thing. If it presents pitched forward just a bit your idea might work and you can flatten an area towards the edge on the bottom of the blade.

I have a small LN and a large Stanley... The LN presents pitched forward, & Stanley presents pretty flat. If I tried what you're thinking on the Stan the heel of the blade would hit lumber before the edge.

It's such a small blade I can't imagine there is anything to be gained using the ruler trick.

Dan Faia's article on router plane setup is second to none... https://www.finewoodworking.com/project-guides/handplanes/why-you-need-a-router-plane

I agree that is not how a new router plane blade should look. It could be fixed with a grinder by first focusing on getting the edge straight using the flat side of the spinning, grinding wheel. I would first use a small combination square and sharpie mark and frequently check progress. Once that is square, I would mark sharpie across the face of the blade and grind the center between the front edge and the rear of the bevel trying not to go past either. Then I would go to medium and fine diamond stones and next stones coarser to finest. Last I would use a leather strop.

The bottom of the blade -- that part that is closest to the wood -- needs to be flat. It should be angled up and away from the cutting edge while in use. It should stay flat and polished.

The top part -- the one that you can look down at while using the plane -- you can certainly alter. I wouldn't say this is a spot for the ruler trick. But you can certainly make a secondary bevel. The rest of that side can stay ratty, as it never cuts anything.

The plain answer is “Don’t do it”. The router plane depends on the blade edge to be flat as flat can be on the bottom. It will cut the surface but won’t yield the results for a precision surface depth if it’s not flat. The tapered edge could make it harder to push the plane through the wood due to the extra drag.

An update: Rockler asked for a picture of the blade, which I provided, and they said they are sending out a replacement blade. In the meantime I've continued to work on the blade, out of pure stubbornness.

Since I don't have a grinder I restarted the back flattening process by going to wet 'n dry sandpaper on glass and and this point have worked the back up to 420 grit. That has eliminated most, but not all of the saw tooth, and the "cutting edge" isn't going to end up completely square, which I assume isn't a problem.

Since I'm getting to the point where further flattening with finer grits isn't going to eliminate the remaining saw tooth, (I don't think). is it better to go back to the coarse sandpaper to shorten the blade past the remaining saw tooth or to try and eliminate that by working on the top bevel? I've worked on the top bevel just a bit to take the wire burr off due to flattening of the back, and I find the bevel difficult to work on due to its size.

The flattening of the back of the blade, the part you don't see while using it will determine the flatness of the cut and should be done with care.

If the back of the blade has a ramp to it side-to-side it will be the equivalent of having a plane blade sticking out farther on one side and cutting deeper...you'll never have a completely flat-bottom cut.

Once the back is flat and true polish it like you would the back of a chisel & you'll pretty much never touch it again. Sharpening and honing will be done on the top part that you can see when you are using it.

TGY - from this point I would finish polishing the back up to the highest grit you have, and then work the bevel until you have a straight edge. These are small blades and shouldn't require too much work, but I agree they can be awkward to sharpen. That's one advantage to the Veritas blade that can be removed from the stem.

Good job so far. I would concentrate on the bottom and not worry too much of what little is left of the saw tooth. It will disapprear during normal sharpening routine.

Yup. The sawtooth will disappear when you hone a microbevel on the top of the blade. But the flat bottom has to be polished a lot more, same as the flat back of a chisel.

You are going to need to create a new bevel on this blade.

It is indeed possible to do so with a back bevel using the Ruler Trick (Chris Schwarz does this), however you are in constant danger of reducing the clearance angle.

Instead, you may wish to try this method I developed some years back ...

http://www.inthewoodshop.com/WoodworkTechniques/SharpeningRouterPlaneBlades.html

Vic Tesolin made a video of it for FWW ....

https://www.youtube.com/watch?v=cuNu-GlgH88

Regards from Perth

Derek

@ derekcohen

I like the method! Unfortunately I don't have a drill press either so I'll soldier on using sandpaper and water stones to flatten the back and then attack the bevel. But what a slick and easy way to sharpen these blades!

In a different forum somebody did caution about reducing clearance too much by introducing a back bevel so I'll hold that in abeyance for the moment.

The plain answer is “Don’t do it”. The router plane depends on the blade edge to be flat as flat can be on the bottom. It will cut the surface but won’t yield the results for a precision surface depth if it’s not flat. The beveled edge could make it harder to push the plane through the wood due to the extra depth below the cutting edge.

Final update.

I have put way too many hours into this plane blade, trying to get it right, and it still is not done. Since the replacement blade Rockler sent just showed up yesterday afternoon I set this one aside for the time being.

I did continue the polishing of the back of the blade up to 1,000 grit on wet and dry sandpaper. That additional polishing did not eliminate the final bit of "saw tooth" on the blade's cutting edge but did reveal that the area right near the back's cutting edge still needed work. That detail wasn't apparent to me at the 400 grit level (pictured above), though at that point I did have a burr on the bevel side of the blade.

I started to work on the bevel edge and determined that the bevel itself is not all in the same plane. Using a higher (finer) starting grit than I used on the back, I could get a nice polish on most of the bevel "behind" the cutting edge, but this would polish would not reach the edge. The toe of the bevel seems to "fall off" from left to right as you look down at the top of the bevel, leaving an untouched (or barely touched) triangle of steel.

Since these blades have a downward slope relative to the post that goes into the router plane I'd expect that the ruler trick would work here as long as you left some amount of clearance behind the cutting edge. In this case it's not all that important that the back of the blade is "flat" as long as the cutting edge is square to the post.

Looking at the plane overall it's clear to me that Rockler's India supplier doesn't place a great deal of importance on the fit and finish of what they're pushing out of the factory. Of course the blade itself was a dead giveaway to that, but the milling work on the ductile iron body backs that up. I've had to reach for my tap and die kit for every threaded hole in the body and to straighten out mangled threads in the screws.

“[Deleted]”

You get what you pay for, don’t you.

@RobertEJr

Sometimes that's true and sometimes it's not.

I bought this plane - as I expect others did - because Rob Cosman gave it a good review after a side by side comparison with the Lie Nielsen plane. Given that the Bench Dog plane at the time was $75 cheaper than the Lie Nielsen, coupled to the fact that the Lie Nielsen plane was unavailable (and still is) it seemed like a reasonable buy.

Given my experience I have a sneaking suspicion that somebody at Rockler noted the name "Cosman" on the order and dug through their inventory to find the very best example to send out. The lack of "quality" in the plane I received was evident in more than just the blade itself, as I've noted above.

To put the final nail in this coffin, I did manage to sharpen the replacement blade adequately but when I went to install the blade in the plane it turned out that the "post" of the blade was too short to allow it to be installed! There was no way to get the "washer" portion of the adjusting nut into the post's machined groove.

All in all very disappointing, a clear example that there's really no care at the factory or at Rockler's to provide a quality product. I have returned the plane and asked for a complete refund.

This forum post is now archived. Commenting has been disabled