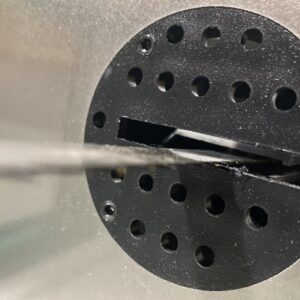

Bandsaw blade too close to insert

Just put together my new Rikon 14” bandsaw (10-326). But after a closer inspection, the blade is touching the side of the table insert. I can’t figure out how to adjust it. Granted this is my first bandsaw, but I’m not new to wood working. Am I missing something simple here?

Replies

Is it symmetric?

If not, can you flip it upside down?

Can the entire table top be adjusted?

The insiert seems to be symmetric, and it looks like adjusting it wouldn't fix it. The table is bolted in from the bottom and I didn't see any way to adjust it parallel to the floor, only rotating it for beveled cuts.

Check the mounting bolts for your table again. Unless your Rikon works differently than my Delta the bolts go through over sized holes so that the table can be properly aligned. You should be able to loosen the bolts and then move the table to center it on the blade. At the same time, make sure you keep the miter groove parallel with the center line of the blade.

Good call! There was some wiggle room in the bottom of the plate and loosening those bolts allowed me to better align it to the blade.

Its plastic. Just cut it out a little more. Put it on top of a piece of wood that will span the hole and trim right there on the saw. You can also make your own out of wood.

The bolts that hold the table to the frame go through oversized holes to allow adjusting the table centered and parallel in relation to the blade. My guess is that along with the table not being centered, the miter slots are not parallel to the blade.

Part of tuning up a new saw. Start by checking the "direction of cut" to the miter slots, then the rip fence. Get them dialed in now and avoid frustration later. Snug up the table very slowly in a rotating pattern to avoid yanking it out of place. It might take a few tries anyway. Do the setup with the widest blade you plan to use on the saw.

This forum post is now archived. Commenting has been disabled