Shop Made Uprights for a Modular Wall Unit

These uprights hold all the cases on my midcentury wall unit. The pairs of 45° holes along their length make the whole unit modular—so the cases can be rearranged. Accurate and consistent holes are crucial. An angled drilling block and a drilling spacer are the keys to pulling it off.

Drilling block nails the angle

The block lets you drill the angled holes in the uprights. A notched block glued to the drilling block provides clamping purchase. I used a 3⁄8-in.-dia. Kreg high-speed-steel step drill bit to drill the holes.

Drilling spacer adds consistency

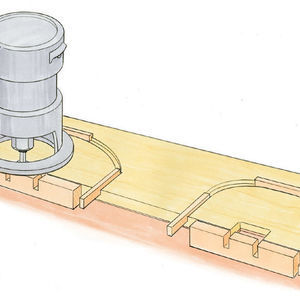

A plywood spacer straddles the upright, and has evenly spaced slots for the drilling block. When you build the spacer, use the drilling block as the guide to locate the spacer blocks.

Drilling the holes

On a flat surface, making sure the work is elevated enough that you aren’t drilling angled holes into the surface below, clamp the drilling spacer onto the upright. Be sure to precisely register the bottom of the upright to the top of the jig, and clamp the drilling block in the first slot on the spacer. Drill the holes, move the drilling block to the next slot, and then repeat all the way down.

From Fine Woodworking #276

Free Plan: Mid-Century Modular Wall Unit

Anissa Kapsales’s wall-unit features mitered cases

combined with a unique hanging system for versatile storage

By Anissa Kapsales #276-July/August 2019 Issue

Fine Woodworking Recommended Products

Incra Miter 1000HD

MicroJig Matchfit dovetail clamps

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in