Two Nailers You Need

These handy tools will make your life easier and your shop time more productive

Synopsis: Is there a place for nails in fine furniture? Many well-respected woodworkers think so. Brads and pins can be a speedy substitute for clamps and are a great way to attach glue blocks, case backs, and other parts where the holes won’t show. There are two basic types of nailer appropriate for woodworking: pin nailers, which fire tiny, headless nails that leave practically invisible holes; and brad nailers, which shoot a larger fastener with more holding power. Depending on the type of work you do, one or both might deserve a home in your workshop.

Some woodworkers think there’s no place for nails in fine furniture, but professionals like Gregory Paolini, Tony O’Malley, and Roland Johnson all find small air nailers useful in their woodworking. Brads and pins can be a speedy substitute for clamps and a great way to attach glue blocks, case backs, and other parts where the nails won’t show. Where the nail holes will be visible, colored wax pencils are a quick and effective fix. And even those woodworkers who don’t use them on their projects find nailers invaluable for building jigs and shop fixtures. It’s also a great tool to have around the house for trim work and improvement projects.

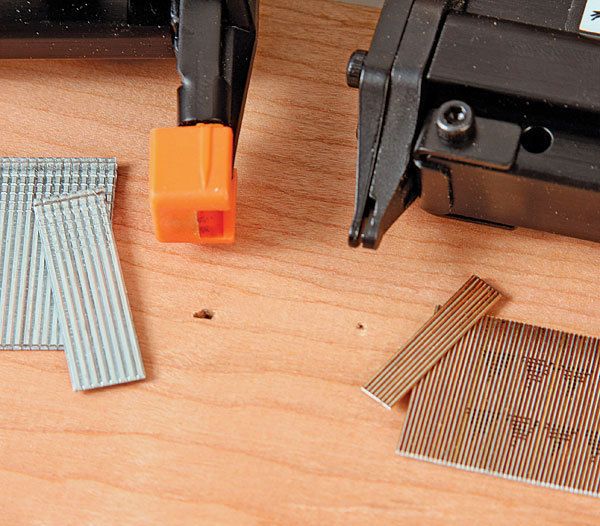

There are two basic types of nailer appropriate for woodworking: pin and brad. Pin nailers are a relatively new breed, and fire extremely small headless nails. They don’t have a lot of holding power on their own, but they work great when the joint is backed up with some glue. And the hole is so small it practically disappears.

Brad nailers shoot a larger fastener, up to 2 in. long, and leave a larger hole, but offer more holding power than pins. Most of the woodworkers I spoke with think it makes sense to have both a brad and pin nailer, especially since they’ve become so inexpensive. But if you’re just starting out, read on to see which type makes sense for you.

What to look for in a nailer For brad nailers, you’ll want an adjustable depth-of-drive. Without it, you’ll have to control fastener depth by adjusting air pressure at the compressor. This can be inconvenient, especially if you’re fastening materials of varying thickness or density. Pin nailers countersink every time, so they don’t have a depth-of-drive adjustment.

Be sure to check out the nosepiece, as some have rather bulky rubber covers that make it tough to see where you’re placing the nail. The best guns have slim rubber or plastic tips that protect the work and provide an unobstructed line of sight. You’ll also want to decide between a conventional or oil-free model. This mostly applies to brad nailers. All the pin nailers I’ve seen require oil, but Porter-Cable just introduced what they claim is the first oil-free pin nailer (model PIN138). If you’re considering an oil-lubricated model, look for one with a rear exhaust, which will direct any oil spray away from your project.

From Fine Woodworking #217

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Makita SP6000J1 Track Saw

Milwaukee M12 23-Gauge Cordless Pin Nailer

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in