Mill Lumber Safely

A bandsaw and a jigsaw make the process less intimidating

Synopsis: The process of turning rough sawn stock into flat, smooth boards can be tricky. The wood is rarely straight or flat to begin with, and the process of getting it so can release inner tensions in the wood that can pinch or bind a sawblade, resulting in dangerous kickback. Michael Fortune eliminates much of the danger by using a bandsaw instead of a tablesaw for initial ripping and by using a jigsaw instead of a chopsaw for crosscutting stock to rough length. Following along as he demonstrates his simple, straightforward method.

The switch from using surfaced lumber to milling your own boards from rough stock is a watershed for most woodworkers. It saves you money, unchains you from the standard thicknesses available in surfaced lumber, and gives you greater control over the accuracy of your work and the look of your boards.

But this business of taming roughsawn stock can be a challenge. The wood is rarely flat to start with, and it often releases inner stresses when cut that can pinch or bind a sawblade, resulting in a violent kickback.

I eliminate these dangers by using a bandsaw instead of a tablesaw for initial ripping and by using a jigsaw instead of a chopsaw for crosscutting rough stock to length. Both of these saws employ narrow blades that make them less susceptible to binding.

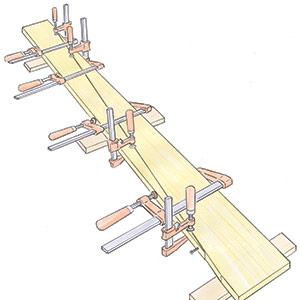

Besides being safer, the process I follow is simple and straightforward. Make sure your machines are set up properly and check the stock with an accurate square as you progress through these steps. your goal, of course, is boards that are completely flat, straight, and square.

Start with the jigsaw and the bandsaw

Rough lumber that is twisted or cupped won’t sit flat on a chopsaw. As the cut is made, the stock can drop into the blade, pinching and binding. For this reason, I use a jigsaw with the stock set across three or (better still) four sawhorses. A jigsaw with an oscillating cutting action and a very coarse blade will cut through the hardest wood up to 2 in. thick.

Always cut off the rough ends of the boards, which may be checked (cracked) and embedded with grit, staples, and other debris that could nick your jointer and planer knives. Now use the jigsaw to cut the rough stock into pieces that are 1 in. or 2 in. over the finished length.

From Fine Woodworking #196

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in