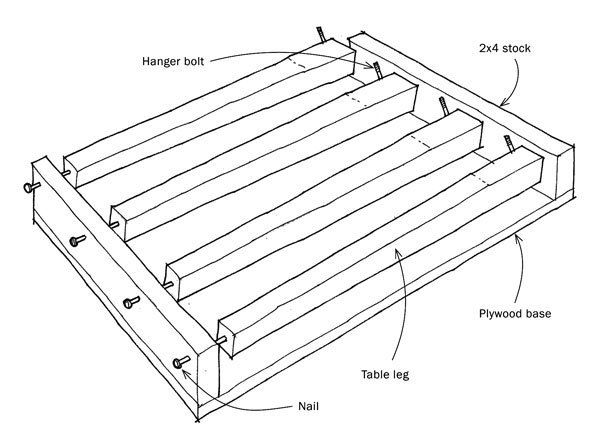

Table-Leg Finishing Jig

Finishing some table legs recently, I discovered how difficult it can be to get a spotless, dripless finish on such parts. The project became a lot easier after I built this rack from scrap.

The rack is just two lengths of 2×4 stock screwed to a plywood base. Common nails serve as spindles. Allow about 1/2-in. of clearance on either side of each leg. Drill holes the same diameter as the nails in the 2x4s at appropriate intervals. Make some indentations in the top and bottom of each leg to act as bearing points for the nails.

In my leg design, I installed hanger bolts for attaching the legs. The hanger bolts also allowed me to freely spin the legs to reach all sides. If hanger bolts are not part of your design, affix a screw in some hidden area of each leg so that you can grip the leg without touching the finish.

Drawings by Jim Richey.

Drawings by Jim Richey.

Fine Woodworking Recommended Products

Odie's Oil

Hedgehog featherboards

Osmo Polyx-Oil

Log in or create an account to post a comment.

Sign up Log in