Thickness-Planing on the Jointer

Tage Frid, in Fine Woodworking #19, p. 94, describes how to thickness boards on the jointer. Frid’s jig is a precision wooden affair that requires removing the jointer’s fence to work. Here’s a simpler way. From a signmaker obtain two 1-in. strips of flexible magnetic sign backing and glue each to a hardwood strip to produce two 1/2-in. thick sticks as long as the infeed table. Glue a hardwood block on the end of each strip to keep it from creeping into the cutterhead.

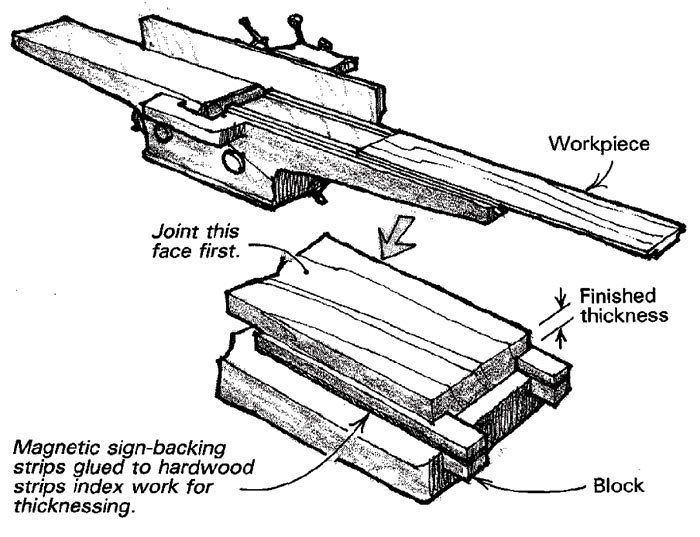

Before using the setup, first joint one face and both edges of the board to be thicknessed. Rabbet the edges, as shown on the workpiece in the sketch.

Now snap the two strips in place on the infeed table so the rabbets ride the strips like rails. Run the workpiece down the rails, across the cutterhead and onto the outfeed table. In this manner, it is the uniform rabbet that indexes the work; the irregular face doesn’t touch the infeed table at all. Start with a light cut, then gradually lower the infeed table with each pass until the rabbets are only 1/16 in. deep. On the last pass, just skim off the wood down to the rabbets to produce the final thickness.

The magnetic strips can be easily adjusted to different-width boards, and there’s no need to remove the jointer’s fence to use them. When the job is done, it takes all of three seconds to convert your thickness planer back to a jointer.

Robert Edmondson, Bowmanville, Ont., Canada

Fine Woodworking Magazine, October 1984 No. 48

Fine Woodworking Recommended Products

Forrest Woodworker II Blade

Starrett 12-in. combination square

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in