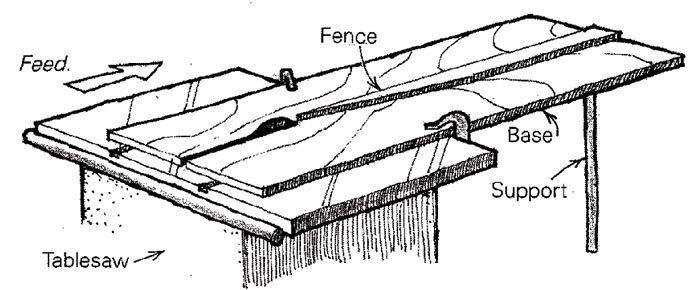

Table Saw Jointing Fixture

I wouldn’t try this setup on a board shorter than 10 ft., but one of the handiest jigs in my shop is a tablesaw setup for straightening the edges of 1-in. hardwood boards. It does the same job as the jointer, but it is faster and more convenient for the 18-ft. boards I use in my boat shop.

To build the jig, joint a 7-ft. long 1×2 and cut a long tapering point on one end. Glue the 1×2 to a 3/4-in. plywood base, about 8 ft. long. Cut a slot in the base in front of the fence for the tablesaw blade.

To use, clamp the fixture to the saw table with the 1×2 fence flush with the left-hand face of the sawblade at its rear edge. Support the tail of the fixture so that it’s level. As you pass a board over the sawblade, the waste edge is split away by the long bevel. Press the board tight to the 1×2 fence to get a straight edge.

You do have to freehand the first 6 in. or 7 in. of the cut, as the board must pass the sawblade before it picks up the fence. Freehand cuts can easily kick back, so be careful.

Colin Pittendrigh, Bozeman, Mont.

Fine Woodworking Magazine, February 1984 No. 44

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

Bessey EKH Trigger Clamps

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in