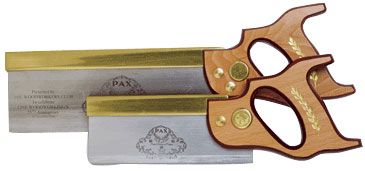

Thomas Flinn and Co. - Pax No. 1 8-in. Dovetail Saw

This dovetail saw from Thomas Flinn and Co. features a 20 teeth-per-in blade and has a handle set to a comfortable angle.

This test evaluated 11 Western-style dovetail saws, from $10 to $125. I used each one extensively in cherry, oak, and maple, making cuts with the grain and across it. I observed how fast each saw cut, the ease with which it started a cut, how smooth the saw was throughout the cut, and how well it tracked a line. I also checked the saw’s quality of construction and ergonomics. Pax saws are made by Thomas Flinn, the same company that produces the Lynx saw. The Pax No. 1 came with a quality sharpening job and cut quite smoothly. It was easy to start, but the kerf was wider than needed, making it wander a bit more in the cut. As with the Lynx saw, the large handle encroaches on the blade, reducing the stroke length for cuts deeper than 3/4 in.

Earlier Review (1/1/2002) by Ian J. Kirby

I recently tried a pair of handsaws from Thomas Flinn and Co. of Sheffield, England. The 8-in. dovetail saw and 12-in. tenon saw carry the venerable Pax label, a highly regarded name in saw making that dates back to the 18th century.

The handles are both roomy and comfortable. And they’re set at an angle that allows for good control of the blade.

Out of the box, both blades were straight and flat, in large part because Flinn didn’t skimp on the back—the brass strip that runs along the top edge of the blade. Also, I was pleased to find that the brass back was aligned parallel to the cutting edge of the blade. That’s important, because you’re able to get the best sense of the cutting plane by observing the back rather than the teeth.

Compared with the tenon saw, the dovetail saw has more teeth per inch (20 vs. 13) and a thinner blade (0.020 in. vs. 0.028 in.). As a result, the dovetail saw makes a thinner kerf and a smoother cut. But don’t expect the dovetail saw to cut better tenons. That’s because most tenons require too much cutting for a thin blade. So a thinner blade generally tends to wander from the line.

When put to wood, both saws worked well, and both cut in a straight line. However, the kerf of the dovetail saw was wider than I prefer, the result of a little too much set to the teeth. And there was slight tearout along the face of the wood, a sign of unevenness in the set. Not that I was surprised such quirks are common on new handsaws.

It took just a few minutes with a fine sharpening stone to get the saw cutting perfectly. With the blade on a flat board, I placed the stone flat on the side of the blade and worked the stone from end to end along the teeth. Three gentle strokes on each side are normally sufficient. Don’t overdo this procedure or the kerf could end up too small to be effective.

Expect to spend $70 for the dovetail saw and $75 for the tenon saw.

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Lie-Nielsen No. 102 Low Angle Block Plane

Bahco 6-Inch Card Scraper

Log in or create an account to post a comment.

Sign up Log in