Copying Cornice Molding on the Tablesaw

While remodeling a Victorian-style wood-paneled bathroom, I needed one 5-ft. length of cornice molding to complete the job. After striking out with local suppliers and running up some hefty long-distance phone bills, I found that it would cost about $150 to make the custom knives to run one 5-ft. piece of molding.

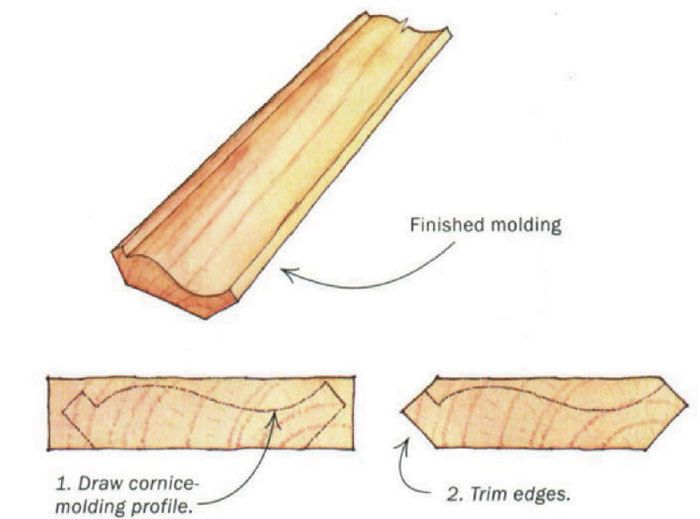

Recalling the many times I’ve cut simple cove moldings on my tablesaw, I had a sudden brainstorm that would enable me to make the cornice in my shop. First, I drew the molding profile on both ends of a blank, a little longer than 5 ft. Then I made two 45¡ bevel cuts on each edge of the blank to define the top and bottom edges of the molding. Next, I built a cradle of 1/2-in. medium-density fiberboard (MDF) a bit longer and slightly wider than the workpiece. I screwed the workpiece to the inside of the cradle, facedown, as shown. The cradle eliminates the problems that would result from cutting away the surfaces of the molding if I tried to mill it directly, facedown on the saw.

I made a series of cuts to define the profile, working from both sides of the cradle. For each cut, I tilted the blade to cut as close to 90¡ to the face of the curve as possible. This makes a cleaner profile and minimizes some of the steps and grooves that have to be scraped and sanded away to complete the shape. After some sanding, I had a cornice molding that was indistinguishable from the original and the satisfaction of proving to myself that it could be done. I also saved $150 to boot.

Ross M. Greer, Alexandria, Ont., Canada

Fine Woodworking Magazine, June 1999 No. 136

Fine Woodworking Recommended Products

Blackwing Pencils

Double Sided Tape

Woodriver Circle Cutting Jig

Log in or create an account to post a comment.

Sign up Log in