Wipe-On Finish Test

Many perform well, but the winner is the least expensive

Synopsis: Consulting editor Chris Minick put 17 wipe-on finishes to the test and discovered that the best performers weren’t necessarily the most expensive. His study included the following: Hydrocote Danish Oil, Watco Wipe-On Poly, Minwax Wipe-On Poly, Watco Natural Danish Oil, Sam Maloof’s Poly/Oil Finish, Sutherland Welles Tung Oil High Luster, Minwax Antique Oil Finish, Sutherland Welles Wiping Varnish High Luster, Tried & True Varnish Oil, J.E. Moser’s Natural Danish Oil, Woodcraft Clear Urethane Oil Finish, General Finishes Seal-A-Cell/Arm-R-Seal, Waterlox Original High Gloss Finish, Waterlox Original Sealer/Finish, and J.E. Moser’s Polymerized Tung Oil.

Like many amateur woodworkers, I rely on wipe-on finishes to bring out the best in my projects. These varnish/oil blends, known collectively as Danish oils, are a mixture of varnish resins, solvents, chemical driers, and linseed or tung oils. They give woodworkers the best of all worlds: easy application, quick drying time, and good protection.

However, while doing research for a recent article on oil finishes (see FWW #177, pp. 22-26), I became intrigued by the differences between pure-oil finishes and oil/ varnish mixtures. The scientist in me took over, and I ended up doing a full-blown study of 17 wipe-on finishes. A few were outstanding and have found a permanent place in my finishing arsenal. Others will never see the inside of my shop again.

Selecting products, preparing samples

There are dozens of wipe-on finishes and I couldn’t test them all, so I tried to get a representative sample. I included a water-based finish and both tung-oil and linseed-oil-based finishes in a price range of less than $6 a quart to more than $40 a quart. Wipe-on finishes typically fall somewhere between pure-oil finishes and brushed-on finishes in terms of build and protection. To represent these boundaries, I included Minwax Fast-Drying Polyurethane, a widely available brushing varnish, and pure boiled linseed oil.

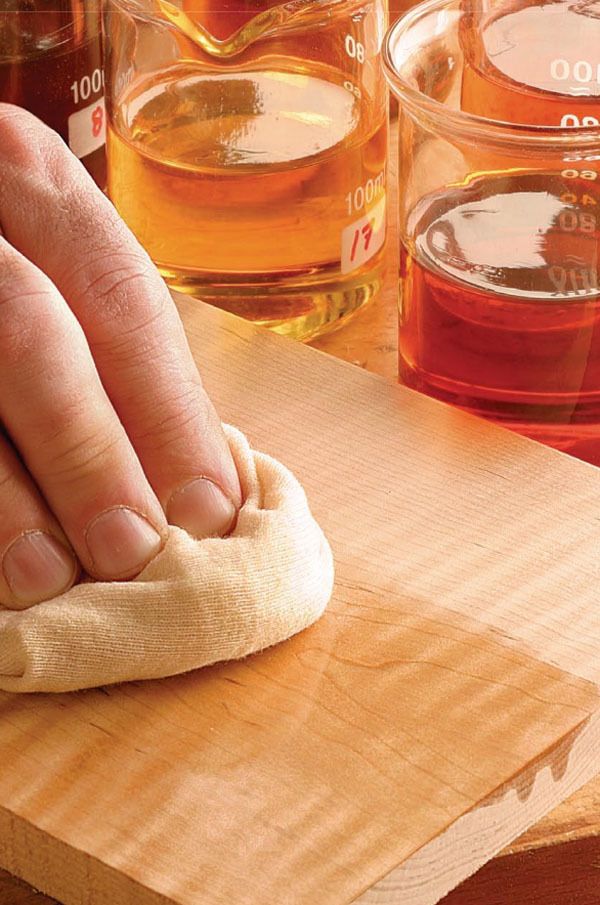

All the finishes were tested on 12-in. by 16-in. pieces of red-oak plywood cut from the same sheet. Each piece was sanded us – ing a quarter-sheet pad sander equipped with P120-grit paper followed by handsanding with P180-grit paper. The sanding dust was vacuumed off, and three coats of each finish were applied to separate panels. I applied the first coat with a lintfree cloth, adding more finish as dry spots appeared. After 15 minutes, I wiped off the excess and allowed the panel to dry for 24 hours.

To see how each additional coat built the finish, I taped off a quarter of the panel and applied the second coat in the same way as the first, except this time it was wet-sanded with a gray Scotch-Brite pad that equates to about P220-grit sandpaper. Coat three was applied to half the panel and sanded in with a gold Scotch-Brite pad similar to P1000-grit sandpaper. I let the panels dry for two weeks before begin – ning the tests because by that time most oil-based finishes are 95% cured.

From Fine Woodworking #178

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Diablo ‘SandNet’ Sanding Discs

Waterlox Original

Comments

In the final chart there is no products listed

Imagine pages 5 and 6 in the PDF are side by side as they would be in a magazine. You can see that the product name list on page 5 would line up with the data on page 6. I’ve attached an image in which I’ve combined the tables from each page.

poolguy,

I believe the chart shows the result of the finishes in the same order they are displayed in the small bottles, i.e. the first result is for the Hydrocoate Danish oil finish. The second is for the Watco Wipe-On Poly Finish etc.

I agree the chart is near impossible to make sense of. There are more rows than cans of product and the prices are out of whack with the main article, ie. the Minwax Poly is $5.95 in the text and, I think, $7.95 in the chart, but who can tell because there's no product name.

Edit: OK, the chart shows color listed from light to dark. Minwax Poly is #4 etc.

Wow! I don't know if you mis-handled the Tried and True when you transferred it into another container, or you didn't apply it properly, or what you did wrong. I've used this product for more years than I like to admit and it would appear we're talking or have experienced two separate products. Maybe the issue is the simpler products are just easier for you to apply and have the best results with. I've had first year apprentices install T&T that have had better results than you came up with. By the looks of the rag you're using in the picture to rub a finish on...maybe you should start there.

Log in or create an account to post a comment.

Sign up Log in