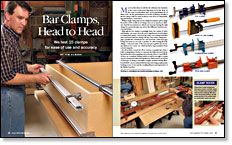

Bar Clamps, Head to Head

We test 15 clamps for ease of use and accuracy

Synopsis: When you think about it, the predominant tool in the workshop is the clamp, which is used in almost every facet of cabinetmaking and furniture construction. While a single clamp may not be a large investment, a full set can cost as much as a tablesaw. Author Tim Albers tested a number of clamps, including pipe clamps, parallel jaw clamps, aluminum bar clamps, and steel bar clamps, to measure their clamping strength and all-around quality. Albers also put together his recommendations for the essential set of clamps.

Most woodworkers would list the tablesaw, the bandsaw, or the router as the most important tool in the shop. In fact, most woodworkers start out by purchasing one of these tools. Yet the predominant tool in the workshop actually is the bar clamp, which is used in almost every facet of cabinetmaking and furniture construction.

While a single clamp may not be a large investment—prices range from $15 to $50—a full set of clamps can cost as much as a tablesaw. And the investment is a critical one, because having the right clamp for a particular glue-up can be the difference between success and failure.

Although the bar clamp is seemingly basic, the variety of styles and features can cause even the most experienced woodworkers to scratch their heads. I surveyed the major tool catalogs and Web sites and found that bar clamps fall into four major categories— pipe, parallel jaw, aluminum bar, and steel bar—with each type being a bit better at one task or another. So, after testing all of the clamps, I selected some of the best and put together my recommendations for a basic set, which includes representatives from several categories.

For all models, I tested the 48-in. version, a standard size. First, I built a testing fixture (below) to measure the deflection in both the bar and the jaws when applying various levels of force. I used 600 lb. of force as a standard setting, which would be enough to clamp 3 sq. in. of joint area with most hardwoods. Then I used a set of four of each type of clamp to assemble a simple, medium-density fiberboard (MDF) carcase (joined with biscuits) and a large poplar panel, looking at ease of use and the resulting flatness and squareness of the finished product.

From Fine Woodworking #172

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Veritas Precision Square

Bahco 6-Inch Card Scraper

Log in or create an account to post a comment.

Sign up Log in