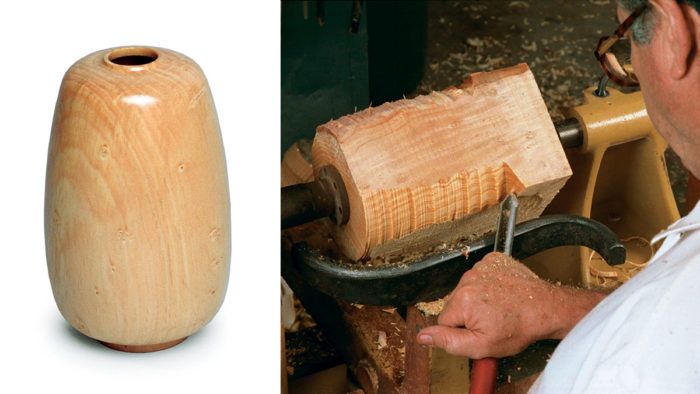

Turn a Hollow Vessel

With green wood and modern boring tools, thin-walled vessels are within every turner''s reach

Synopsis: Improvements in wood-turning tools have made the art of hollow-vessel turning accessible to woodturners of varying skill levels. In this article, Howard Levin, a woodworking instructor and custom woodworker, guides readers through the steps to turning a tall vessel with a narrow rim from green wood. In addition to touting the joy and ease of turning green wood, Lewin also explains how to keep the vessel walls thin and uniform, and how to dry a green wood turning to release the moisture slowly and prevent checks and cracks.

During the past few decades there has been a revolution in woodturning tools, from lathes and chucks to gouges and boring bars. As a result, what once was deemed difficult or even impossible to turn has become commonplace.

In the area of hollow-vessel turning, two innovators stand out. The first is David Ellsworth, who in the 1970s began turning vessels with small openings. His first tools were scrapers he had bent with a welding torch. Later he developed longer-handled tools with swivel tips that held machinist’s tool bits. These offered more control and safety and could produce a wider variety of enclosedvessel forms. Jerry Glaser, an aerospace engineer and hobbyist wood turner, took the ball from there, working to reduce the long tool’s tendency to catch and jerk downward. He came up with a doublearticulating tip that swivels to place the cutting edge at the tool’s centerline. Other variations continue to emerge, making new vessel forms possible.

I use a Glaser-designed boring bar for my hollow-vessel work. The tool is available from The Woodturners Catalog (800-551- 8876) for $150. The bar is filled with buckshot to dampen vibration. The tip is double-articulated, and a large counterweight attached to the bar reduces the impact of catches, which can be murder on the wrists. This tool’s innovative design makes cutting into end grain much less daunting. The other key to success is using green wood.

Aside from the joy and ease of turning wet wood—ribbons just stream off the workpiece, even in end grain—I also like the subtle way green wood moves and dries. Many turners avoid green wood because of its tendency to crack as it dries. However, as I explained in an article on green-wood bowls (FWW #147, pp. 48-53), the drying process is easily controlled, reducing the likelihood of checking. The first key is to keep the vessel walls thin and uniform, which not only allow the walls to flex but also equalize drying stresses. The second is to wrap the freshly turned vessel in brown paper bags to slow the release of moisture. Following these guidelines, I seldom see checks or cracks.

From Fine Woodworking #154

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Sketchup Class

Log in or create an account to post a comment.

Sign up Log in