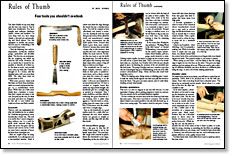

Four Tools You Shouldn’t Overlook

Why a drawknife, shallow gouge, spokeshave, and shoulder plane should be part of your handtool arsenal

Synopsis: Though you may feel your workshop is equipped to perfection, Michael Dunbar has a few tools that you may still need to add. He makes the case for adding a drawknife, shallow gouge, wooden spokeshave, and shoulder plane to your collection, and explains how to best use all these items.

You have finally set up your shop just the way you want it. You’ve built your workbench. You have bought your tablesaw, thickness planer, jointer and bandsaw. On your shop wall you have sharp chisels, a dovetail saw and smoothing and block planes. You feel equipped to handle any project, but you may be overlooking a few very useful hand tools.

I find the following four tools indispensable: drawknife, shallow gouge, spokeshave and shoulder plane. The first two are used generally for roughing; the others are used for fine work. However, all are so handy that it would be impossible to describe all of their uses. Put them to work, and you will soon come up with jobs I haven’t thought of. As a bonus, only the shoulder plane will cost more than $100. The other three tools are priced closer to $50.

With some practice, hand tools like these are faster than machines, easier to control and pose less danger to a semifinished workpiece. While they cut a little more slowly than a bandsaw or router, they don’t require any setup or test cuts. Just pick up the tool, do what you need, and move on. Frequently, the job is over before you could set a fence and flick a switch.

Drawknife

There is only one explanation for why old drawknives are so plentiful. Until this last generation, every woodworker owned one. The tool is so useful that I cannot imagine a shop without one. It is used for quick stock removal along the grain and across the grain and for concave and convex curves. It will cut away heavy amounts of wood far faster than a bandsaw can.

Here are a couple of tips on using a drawknife. It is a slicing tool, not a two-handled hatchet. Hold it askew and draw the edge through the wood the way a butcher slices meat. You will be amazed at how effortlessly and cleanly it works. Use the drawknife with the bezel (the ground surface often called the bevel) and manufacturer’s stamp up. Many woodworkers use the knife upside down, because they think it gives them more control. However, because they cannot take a heavy chip in this position, they sacrifice the tool’s most important ability: fast stock removal. Far better that you learn to use the knife the proper way. You will be able to take paper-thin shavings that rival those made with a plane or hog off slices as thick as your finger.

From Fine Woodworking #150

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in