Synopsis: When you need basic, inexpensive, dependable, simple joints, biscuits are hard to beat. Robert W. Lang gives a quick tour of a biscuit machine and recommends a few tips to help size up the field. He offers information on safe grips and good posture. One of the advantages of using biscuits is dead-simple layout. Biscuits should be dry, so store them in airtight containers so they absorb glue effectively. Lang offers other biscuit basics and recommends using water-based glue. The article includes a full page of biscuit-joint options.

The biscuit machine’s ability to turn butt joints into strong, accurate spline joints in a heartbeat has revolutionized the way cabinets are built. Biscuits are usable in practically any woodworking material, but they are ideally suited for joints in sheet goods such as plywood, flakeboard and medium-density fiberboard (MDF), where they are faster and better than just about any other joint. Biscuits are the Volkswagen Beetle of woodworking joints: inexpensive, dependable, uncomplicated, unfinicky. No one would mistake them for hand-cut dovetails, but when you need basic transportation, they’re hard to beat.

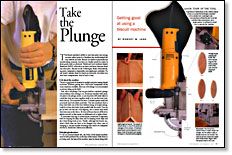

A bit about the machine

There is a good deal of variation in quality and price among biscuit machines. Without getting into a full-scale comparison of the many machines available, there are a few things I can recommend to anyone sizing up the field.

First, take a test plunge. You can get a feel for a machine’s plunge action without even turning it on. Avoid any machine with excessive play in the plunge action, as any slop here will result either in a joint that does not come together easily or in one that won’t perfectly line up. Then examine the fence. It should operate easily and accurately and lock down positively. The best machines have a fence that folds out of the way without losing its height setting. Look for a fence that locks down parallel with the cutter. You can get by with one that isn’t self-aligning, but it means extra work every time you set the fence. Be wary of fences that are difficult to tighten securely or that require an additional tool to tighten them.

A convenient dust bag or vacuum-hose connection is important both for keeping the shop clean and for keeping wood chips and dust from flying back at you. Finally, although the biscuit machine’s blade does not have to be changed very often, ease of changing it, and the number of settings that need to be readjusted afterward, should also inform your selection.

Safe grip, good posture

To cut an accurate biscuit slot, the fence of the biscuit machine must be held perfectly flat on the face of the board. If the fence is not being used, the base of the machine must be placed along with the workpiece on a reliably flat surface. If the machine or the workpiece is tilted at all, the two sides of the joint will not line up.

From Fine Woodworking #133

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Milwaukee M12 23-Gauge Cordless Pin Nailer

Craftsman Random Orbit Sander

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in