Threading Wood for Machine Screws

Cut durable threads in wood with metal taps

Synopsis: Pat Warner discusses the use of machine screws in knockdown furniture joints and adjustable jigs. He explains how to use metal taps to cut crisp, strong, and durable threads in any hardwood. The only specialized tools you need are taps, and he shares tips on making the joint stronger, on drilling pilot holes, and on using a drill press to tap the wood.

Machine screws make excellent joints in wood. They are hard to break, and some of the head configurations are quite decorative. I use them for knockdown furniture joints and for adjustable jigs that need to be strong. But machine screws are not as simple to use as wood screws because they don’t cut their own threads the way wood screws do.

The most common solution is a threaded insert (for more on this, see FWW #120, pp. 79-81). But I’ve found you really don’t need inserts to make strong joints with machine screws. Metal taps will cut crisp, strong and durable threads in any hardwood. It takes about the same amount of force to strip wood threads as it does to pull a threaded insert out of its hole. And if you tap the wood deeper than a threaded insert requires, the wood joint will be stronger. Machine screws in an inch of wood threads will make a really tough knockdown joint.

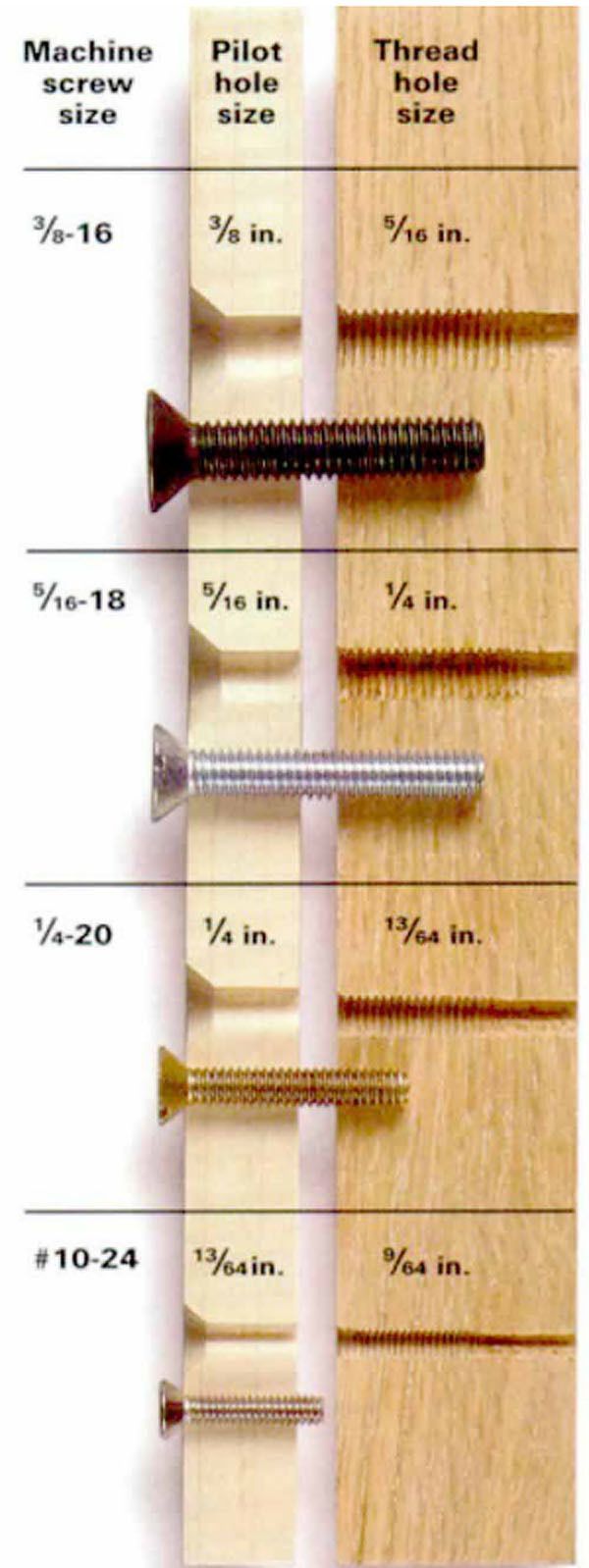

Wood threads require careful drilling and tapping. The wrong size drill bit or a misaligned hole will lead to a weak connection. But by following the drilling schedule at right and using the proper tools, you can produce deep, crisp and strong threads without too much trouble.

The only specialized tools that you will need are taps. I have taps in four screw sizes: -16, -18, -20 and #10-24 (the first number is the diameter of the screw; the second is the number of threads per inch). You will also need drill bits, transfer punches and countersinks.

The pilot holes need to be drilled first to locate the thread holes properly. The machine screw should slide easily through the pilot hole, just as a wood screw should. If the head configuration calls for it, I would countersink the pilot holes for the screw heads at this point.

From Fine Woodworking #126

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Precision Square

Suizan Japanese Pull Saw

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in