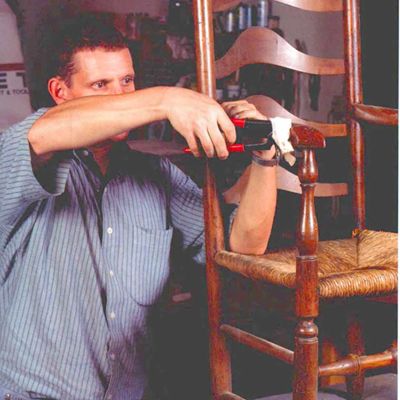

Synopsis: Even the best joints may not hold up to the abuses of feisty 2-year-olds or careless moving companies, writes Jeff Jewitt, a furniture restorer. After enough time, most furniture will need some sort of repair. He talks here about how to remove fasteners and soften glue joints, how to take apart and rebuild a variety of mortises and tenons, and how to replace dowels. Jewitt addresses dovetails (through, half-blind, and sliding) and how to fix legs. Detailed photographs show how he makes all these repairs.

Well-executed joinery will last a long time, but even the best joints may not hold up to the abuses of feisty 2-yearolds and careless moving companies. After the ravages of time and use, most furniture will need some sort of repair.

Recutting original joinery or replacing an entire part may not be the right course if the furniture is a valuable antique. But if your furniture is not destined to become part of a museum collection, repairing a broken joint involves dismantling it and replacing worn or damaged pieces with wood from the same species.

No joint repair can begin until the piece of furniture has been taken apart, and well meaning novices and poorly trained professionals who worked on the piece earlier can make your life difficult. Nails, screws and metal brackets are often installed on loose joints in an effort to repair them. Glue is dribbled into partially opened joints, and hot-melt glue is used too often. Many production furniture pieces were pinned with small finishing nails to hold glued joints together until they set, eliminating the need for clamps, but making disassembly a chore.

Remove fasteners, and soften glue joints

Fasteners need to be removed so the joint comes apart easily. To pry out small nails, regrind the outer jaws of pincers to grab nails set flush with the surface. I find that it’s best to leave nails set below the surface rather than push them through. This will split the mating piece when the joint is pried apart, but that’s easier to repair than the damage done to the visible surface of the wood

With old flat-head screws, make sure the tip of the screwdriver fits snugly in the slot to avoid stripping the head. I keep an old driver on hand that I regrind for a custom fit. For frozen screws, hold a screwdriver in the slot, and heat the shank of the screwdriver with a propane torch to transfer the heat to the screw. After the screw cools, it should come out easily. A screw extractor is the last resort.

Prior to the mid-1940s, hot animal hide glue was the standard for furniture assembly. After that, polyvinyl acetate (PVA) glues took over. A simple test will tell you which glue was used. Place a drop of hot water on the glue, and wait several minutes. Hide glue will become sticky, and PVA glues will turn a milky white (see the bottom left photo).

One attractive characteristic of hide glue is that it is reversible. It can be softened with water and heat or crystallized with denatured alcohol for really stubborn joints.

From Fine Woodworking #125

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bessey K-Body Parallel-Jaw Clamp

Festool DF 500 Q-Set Domino Joiner

Estwing Dead-Blow Mallet

Log in or create an account to post a comment.

Sign up Log in