Making Big Cabinets Manageable

Small parts and knockdown hardware simplify finishing and moving

Synopsis: Niall Barrett came up with a way to build cabinets out of smaller parts, yet not have the end result look like a jigsaw puzzle. Small components are light and easy to move around the workroom and take up less space at every step of the way. Finishes are easy to apply when you work with small components and flat panels, too. He explains how to plan ahead for components and fasteners, including an assortment of knockdown hardware options.

Working in New York City, where most of my clients live, is trying even at the best of times. There’s rarely ever a place to park, so I end up double-parking to unload a delivery, always keeping a sharp eye out for the police. After that, I’m forced to pay exorbitant fees to park my van in a lot. Freight elevators tend to be small and poorly located, and stairways have sharp corners to negotiate. I once delivered a cabinet that would not fit in the elevator, so I had to walk it up two flights of stairs. I was lucky the client didn’t live on the 35th floor. Doors and hallways can be quite narrow when you’re trying to deliver a large cabinet.

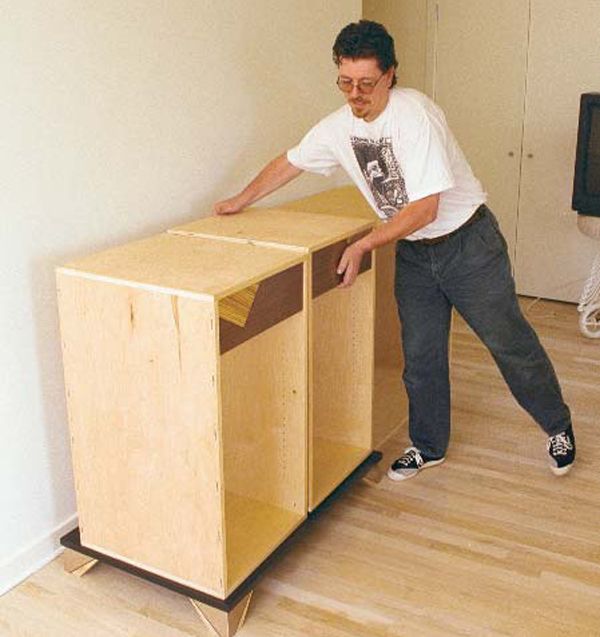

These anxiety-provoking restrictions and horror stories from fellow cabinetmakers are what started me thinking about cabinets in a new way. It became clear to me that smaller parts were the answer. They would be easier to handle and transport. The challenge would be to assemble them quickly and not have the end result look like a jigsaw puzzle of small pieces. These days, I routinely build large pieces, like the stand-alone television cabinet shown above, in easily handled components. When I get to a job site, whether it’s in New York City or elsewhere, I assemble the pieces with knockdown hardware.

This approach is not just for woodworkers who make deliveries to a large city. It also works for the guy building a large pantry cabinet in his garage who will have to move it through the house into the kitchen.

Make cabinets easy to finish and move

Small components are light and easy to move around the workroom and take up less space at every step of the way. For me, that’s important because I work in a fairly small shop in the basement of my house. The ceilings are less than 8 ft. off the floor. I often build units that are too large to put together in my shop; they aren’t fully assembled until they are delivered to the site.

From Fine Woodworking #122

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Circle Guide

Stanley Powerlock 16-ft. tape measure

Bessey K-Body Parallel-Jaw Clamp

Log in or create an account to post a comment.

Sign up Log in