Cutting Sheet Goods Down to Size

Alternative rigs for sawing and routing large panels

Synopsis: Charley Robinson evaluates three guide systems for cutting plywood with a circular saw: the Exac-T-Guide, Glide-Easy Saw, and Blade Runner II. They all use a carriage to mount the saw and a fence or rail system to guide the carriage. He put the units through their paces and talks about how easy they are to set up and how the guides compare on basic functions. A side article discusses the importance of a double-edged cutting guide and a sturdy worktable.

I hate plywood, but I’ve used a lot of it. And I’ve used plenty of medium-density fiberboard (MDF) in my time, too. The inherent stability of sheet goods makes them very convenient for cabinet carcases, built-in units and other remodeling projects. But trying to horse the heavy sheets through a tablesaw can be difficult, particularly if you work alone. And even with a helper, you still need almost 20 ft. of floor space to rip a full sheet.

Large commercial shops and lumberyards have used panel saws for years, but I couldn’t justify $800 to $1,000 for such a specialized tool. My low-tech solution was to use a circular saw and the cutting guide shown in the sidebar on p. 84. The system works great for occasional use but can be cumbersome and time-consuming; the guide needs to be realigned and clamped for each cut.

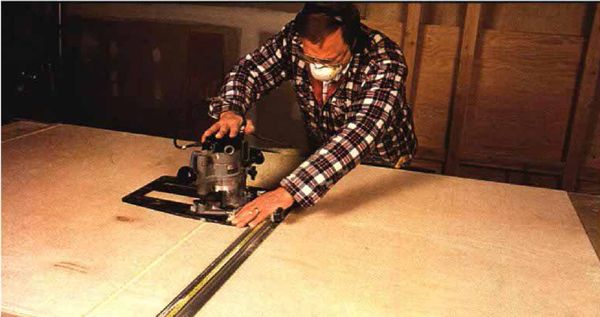

At recent trade shows, three guide systems for cutting plywood with a circular saw caught my eye. Exac-T-Guide, Glide-Easy Saw and Blade Runner II (see the photo above and the photos on the facing page) all use a carriage to mount the saw and a fence or rail system to guide the carriage. Each manufacturer claims their guide system will rip and crosscut full 4×8 sheets, and two say they will replace the tablesaw for cutting sheet goods. The cost for these units, including the extras you will need to set them up for cutting plywood, ranges from $215 to $235. In addition, the systems all have router capabilities or will in the near future.

I wanted to try out these systems, so I designed and built some closet organizers and several sets of bookshelves to put the units through their paces. Typical of most sheet-good work, these projects required ripping panels to width, crosscutting them to length and routing dadoes and grooves. If you’re used to working sheet goods on a tablesaw, it will take an open mind to see how versatile these tools can be. For example, when making a bookcase, shelf dadoes must align. With one of these units, I was able to rout dadoes across the panel before ripping it into individual bookshelf sides, thereby ensuring alignment. I’ll describe how each system is set up and how they performed these basic functions.

Glide-Easy Saw

The Glide-Easy system suspends a circular saw above the workpiece on a pair of aluminum brackets. Nylon rollers ride along some 2-in.-dia., electrical conduit to guide the saw, as shown in the top left photo on the facing page. For $185, Intelligent Product Designs includes the aluminum brackets that clamp to the saw’s baseplate, a pair of plywood glide-rail supports and plywood height-adjustment blocks, as shown in the top right photo on the facing page. To this you need to add about $30 worth of materials: four 10-ft.-long 2x4s and two 10-ft.-long pieces of 2-in. inside diameter (ID) electrical conduit.

From Fine Woodworking #95

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Grout float

Stanley Powerlock 16-ft. tape measure

AnchorSeal Log and Lumber End-Grain Sealer

Log in or create an account to post a comment.

Sign up Log in