Thickness-Planer Primer

Fine-tuning is the key to smooth planing

Synopsis: Despite differences in size and features, all planers operate on the same principles. If you understand those principles, you can adjust your planer properly to obtain consistently flat lumber that’s smooth as silk. The authors explain how planers are made, how to tune them up, adjust the feed roll, set the chip breaker and pressure bar and bed rolls, and how to sharpen and install the knives. They discuss how to operate the planer and handle difficulties such as knots, splits, and checks, and how to troubleshoot your planer. Side information covers adjusting a planer with a dial indicator.

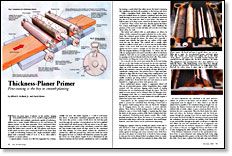

There are many types of planers on the market, ranging from small hand-fed 4-in. to 6-in. models to large production machines with multiple cutterheads capable of surfacing a million feet a week. Despite differences in size and features, all planers operate on the same principles. If you understand these principles, you can adjust your planer properly to obtain consistently flat lumber that’s smooth as silk. The planers we’ll discuss in this article are those most commonly found in the home shop or small woodworking business—the single-cutterhead surface planer with a maximum width of 12 in. to 18 in., often called a “cabinet” or “pony” planer.

A typical planer consists of a flat bed supported by a frame, usually cast iron. The frame supports a HP to 3-HP motor that drives a multi-knife cutterhead suspended above the bed. The motor also powers a series of rolls above the bed that push wood through the machine. A board placed on the bed is grabbed by the infeed roll, which presses it flat and drives it into the spinning cutterhead. Just ahead of the cutterhead, a metal bar called the chip breaker helps break off chips raised by the cutterhead and clear shavings out of the planer. Behind the cutterhead is another bar, called the pressure bar, which also holds the wood flat against the bed. An outfeed roll behind the pressure bar pulls the wood out of the planer. Depth of cut is determined by the distance between the bed and the cutterhead arc and is controlled by turning a crank wheel that either moves the head (containing the cutterhead and feed-roll assembly) or the bed up and down.

Unlike a handplane blade, which slices a single shaving at a pass, the multiple knives in a planer’s cutterhead each take many small shavings as the board is fed past. The cylindrical cutterhead has slots in it that hold two, three or four knives The knives are held in place by locking screws, which let the knives be adjusted or removed. These screws don’t bear directly against the knives, but contact knife-length bars called gibs, which distribute the pressure of the screws evenly and help curl over the wood chips sliced off by the knife.

From Fine Woodworking #70

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Bessey K-Body Parallel-Jaw Clamp

Veritas Precision Square

Log in or create an account to post a comment.

Sign up Log in