Synopsis: Chris Becksvoort designed a straightforward dining table that you can build in a couple days with minimal tools. He says there’s any number of ways you can build it, but he follows a certain order of events. First, he glues up the tabletop several days before beginning construction. He starts construction of the base by making the legs, ripping them all from a single board cut to the exact leg length. The apron, he says, is a tradeoff between ergonomics and aesthetics; he uses short tenons, and assembly takes about 10 minutes. He includes information on adding a leaf.

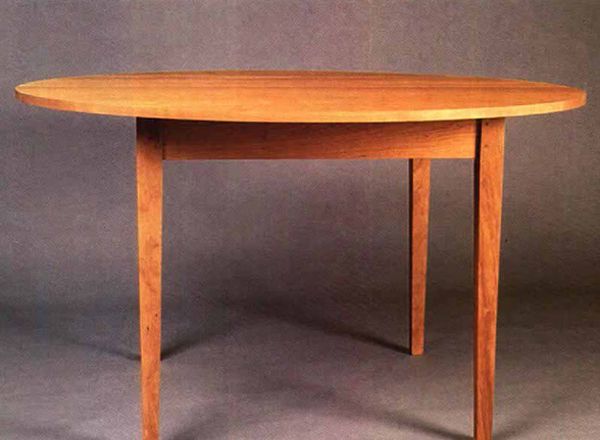

I designed this round table to solve a space problem in a tiny apartment my wife and I once shared. Our dining room was a niche surrounded by three walls, leaving far too little space for a rectangular table. A round tabletop on a square leg-andapron base promised the most usable surface area in the least floor space. I’ve since built about 30 of these tables, some with up to three removable leaves that expand the top to accommodate more people. Over the years, I’ve refined the details a little, but the table remains a straightforward piece you can build with minimal tools in a couple days.

The tabletop is 48 in. in diameter, which will seat four comfortably or six in a pinch if you don’t wish to add a leaf. You can scale the top and base up or down slightly, but wholesale departure from the dimensions given isn’t advisable. The plans call for a 24-in. space between the legs—plenty of room for knees and legs. For a smaller top, you could move the legs a little closer together, but if you scale the top up and widen the leg stance accordingly, spacing greater than about 26 in. will look awkward. Leg spacing is complicated by the fact that a round top overhangs a square base unevenly. As a result, when the apron is viewed from straight on, the table appears to be all overhang; when viewed diagonally, it appears to have too little overhang. By experimenting with a mock-up, I arrived at a visual compromise represented by the dimensions in figure 1. If you need a larger table, I suggest you add one or two leaves instead of gluing up a bigger single-piece top.

Getting started—There are any number of ways to build a legand-apron table, but for expediency, I follow a definite order of events, regardless of the method. First of all, I glue up one or more tabletops several days before beginning construction. When I do my weekly errands in Portland, I drop off the tops at a local millwork house where they’re sanded to 150 grit on an abrasive planer. This machine sanding is well worth the $20 or so it costs: The tops emerge perfectly flat and ready to finish after a final sanding to 220 grit.

Some woodworkers argue that it’s best to glue up a tabletop so the boards’ growth rings are either all up or all down, reasoning that any cupping will be easier to restrain if it occurs in the same direction. Others alternate the growth rings, claiming it’s better to have several small warps than one big one.

From Fine Woodworking #70

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Starrett 12-in. combination square

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in