Preparation of Stock

The essential first step is obtaining a true face side

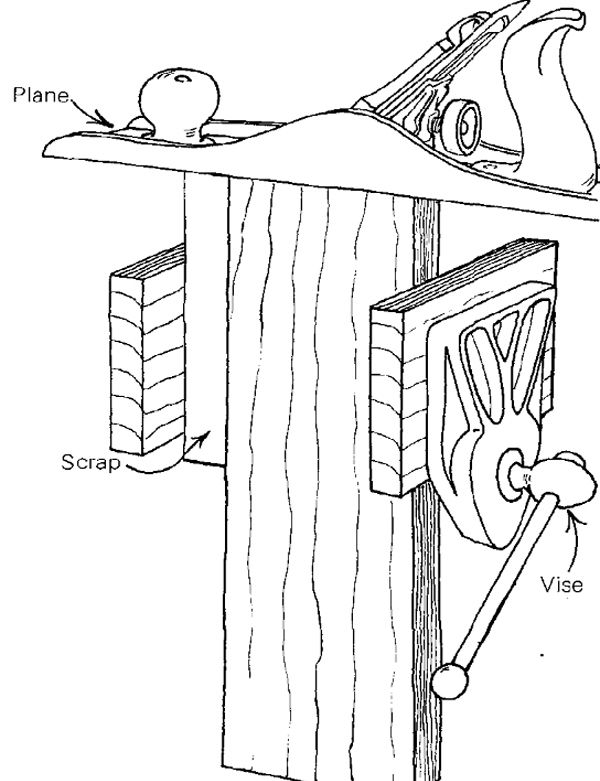

Synopsis: Proper preparation of a face side and from it a face edge are essential preliminary steps in a woodworking project, writes Ian Kirby. If this part of the job is not done correctly, serious problems will arise in all subsequent operations. Kirby discusses the general principles and requirements of preparation before talking about the specifics of obtaining true reference faces. Among other tools, he uses winding sticks, hand planes, a straightedge, and a jointer. The article is rich in drawings that illustrate the steps he describes.

A face side and a face edge are true reference surfaces from which accurate measurements may be taken. Proper preparation of a face side and from it a face edge are essential preparatory steps in woodworking. If this part of the job is not done correctly, one is bound to get into serious difficulties in all subsequent operations.

Preparing a face side that is flat in width, flat in length and out of winding is analogous to pegging out the site on which a house is to be built. If this first step is taken lightly and not accurately carried out, the errors compound at every building stage. No amount of connivance will prevent difficulties from arising at every turn. Yet of all the processes in woodworking, preparation of stock is often woefully done and frequently receives only perfunctory attention. Basic woodworking books do cover the process, and it seems strange to me that in teaching, the case for it must be constantly restated. I find that even quite experienced woodworkers need to be reminded of the procedures to follow. Preparation is so elementary that people seem to treat it with contempt, saving their energies for more interesting operations.

General approach I shall discuss the general principles and requirements of preparation before going on to the specifics of obtaining true reference faces. It’s always unwise to approach woodworking procedures in an ad-hoc manner because in the main there is a sequential logic to them. Preparation is no exception.

For any one job it is best to convert and prepare all of the stock at the same time, whenever it is possible to do so. This usually saves material, time and effort, and reduces the risk of making mistakes. It also ensures that all pieces to be finished to the same dimension are machined (if you are using machines) at the same setting.

Preparation includes or at least begins with the selection of timber for the job, if only because knowing what one has to achieve from a piece of wood has a lot to do with which piece one chooses. However, selection could be considered a topic in its own right and I won’t try to deal with it here. Nonetheless, the two procedures overlap when deciding whether to cut all the pieces directly to the sizes specified in the cutting list, or whether to make it a multi-stage operation by preparing larger pieces from which the correct number of smaller pieces will later be taken.

From Fine Woodworking #13

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Stanley Powerlock 16-ft. tape measure

Hedgehog featherboards

Log in or create an account to post a comment.

Sign up Log in