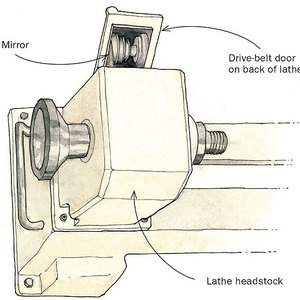

General - Midi-Lathe 25-100 M1

General’s benchtop lathe has a 10-in. swing and offers the capacity to turn up to 15 in. between centers.

Many woodworking shops don’t have a lathe, most likely because of cost or space. But the arrival of a new category of small lathes has made cost and space less of an issue. Introduced in the late 1990s, these machines—often called midi-lathes—are generally bigger and beefier than the so-called minilathes, yet they’re smaller than full-size machines. Midis are affordable—selling for between $285 and $350—and take up very little space. For someone unsure whether wood turning is going to be worthwhile, a midi-lathe might be the best way to test the waters. Not only are the midis relatively inexpensive, they also have enough power to do some serious work. But how well do they work? To find out, I tested five midi-lathes for a semester in my wood turning class at the School of Art and Design at Purchase College in New York.

The General is, by far, the heaviest of the midis, weighing in at 106 lb. At 15 in., it ties with the Fisch for the most distance between centers, without a bed extension. Add the long bed extension, and it provides 45 in. between centers, more than any of the other midis reviewed. A long bed extension is $145; a short extension is $85.

Log in or create an account to post a comment.

Sign up Log in