In my shop, the shoulder plane is the go-to tool for trimming tenon cheeks. The low-angle, bevel-up blade works great across the grain. and because the blade is as wide as the plane body, it can cut all the way into the corner where the cheek meets the shoulder. This ability is also essential when I use my plane on rabbets.

However, despite its name, I typically don’t use a shoulder plane on tenon shoulders. That’s because most tenon shoulders are shorter than the plane is long-not to mention narrow. It’s hard to balance the plane on the shoulder and get a good cut. Instead, I use a chisel. To see how I do it, take a look at 4 Chisel Tricks (Handwork, FWW #221).

More on Sharpening

Bench Grinding Basics

How to Use a Honing Guide

How to Sharpen Jointer Knives In-Place

For best results on tenon cheeks, a shoulder plane needs a flat sole and sides that are square to it. also, the width of the blade should match the width of the body. you might think they come that way from the manufacturer, but it’s actually common for the blade to be a bit wider. So, I’ll show you how adjust the blade’s width, and give you some tips for setting it up for square cuts.

If you don’t already own a shoulder plane, get one that’s at least 1 in. wide. Most tenons are between 1 in. and 1-1⁄2 in. long, and a narrower plane is more likely to taper the tenon.

Check the Plane Body, then Tweak the Blade

A shoulder plane won’t cut a square corner unless it has a dead-flat sole and sides that are exactly 90° to it. So, the first time you pick up the plane, check the sole with a straightedge and use a combination square to check that the sides are square to the sole. If the sole isn’t flat or the sides aren’t square to it, return the plane. Correcting those problems is not worth the hassle.

After checking the body of the plane, turn your focus to the blade. Take it out of the plane, then lay the plane on its side on a flat surface. Hold the flat side of the blade against the plane’s sole and look to make sure the blade is wider than the body. If it’s not, send the plane back. If the blade is too narrow, one side won’t cut into the corner, creating a wider step and pushing the plane farther away from the shoulder with each pass.

However, a blade that’s too wide is also a problem, because it can dig into the shoulder. Ideally, the blade should be the same width as the body, but if it’s 0.001 in. to 0.002 in. wider, that’s OK.

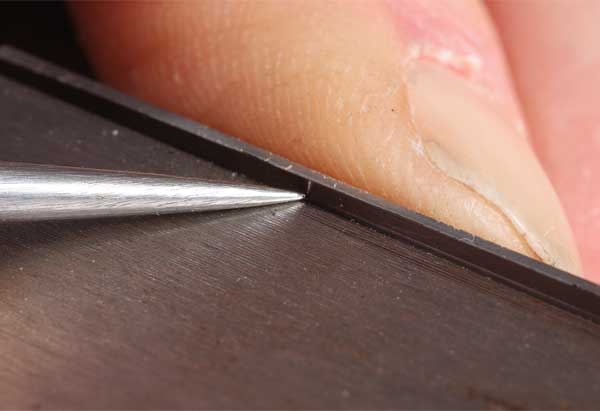

Mark one edge of the flat side of the blade with a permanent marker. Then, with the plane on its side and the blade pressed against the sole, scribe the body’s width on the blade.

Grind it down with a bench grinder (or on your sharpening stones). It’s critical that the two sides of the blade are parallel to one another, so use calipers to check them as you grind. Next, check whether the cutting edge is square to the factory edge. If not, grind it square. Finally, sharpen the blade. I recommend a hollow grind for the bevel. Because of the blade’s shape, it doesn’t fit well in honing guides. The two high points created by the hollow grind make it easier to hone the blade freehand.

Three Step Tune-Up

Intended to cut into square corners, a shoulder plane needs a flat sole, square sides, and a blade as wide as the plane.

1) Check the Body

Now that the blade is sharp, put it back in the plane. When sliding it into the throat, take care not to nick the edge, and be certain that the adjuster mates solidly with the blade. Visually check that it’s centered in the throat.

Next, square the cutting edge in the mouth. First, get it roughly set by turning the plane sole up with the blade projecting beyond the sole. Sight down the sole of the plane from the front. Make lateral adjustments to the blade until it projects equally across its entire width.

Now retract the blade so that it doesn’t cut. Then begin pushing the plane across a piece of scrap and increase the depth of cut as you go. When you start to get a shaving, notice where the blade is cutting. If it’s making a square cut, the shaving will be the full width of the blade. If not, adjust the tang of the blade in the direction of the corner that isn’t cutting. Pinch your fingers around the plane and blade near the cutting edge to keep that end still. Loosen the hold-down and nudge the tang over. Tighten the hold-down. Test and adjust the blade until it’s right. Finally, set the mouth—if that’s possible on your plane—narrow for figured and hard woods and wider for soft woods.

|

| click to enlarge |

|

| click to enlarge |

| Straight and square. Hold the plane up toward a light source. Light sneaking between the plane and a rule means it’s not flat. Replace the rule with a combination square to determine if the sides are 90° to the sole. |

2) Tweak the Blade’s Width

|

| click to enlarge |

| Ink along one edge. It’s much easier to see the scribe line you’ll create against a dark background than against the steel of the blade. |

|

| click to enlarge |

| Mark the sole’s width. Lowe uses the scribe from his combination square, holding its tip slightly above the plane body as a precaution against grinding the blade too narrow. |

|

| click to enlarge |

| Grind to the line. Set the tool rest at 90° to the wheel. Grind away most of the excess, then smooth the rough edge on your sharpening stones. |

3) Square the Cutting Edge

|

| click to enlarge |

| Look into the light. Register the square on the factory edge of the blade (the one you didn’t grind). If the cutting edge is out of square, regrind it. |

Set Up for a Square Shaving

Now that the blade is sharp, put it back in the plane. When sliding it into the throat, take care not to nick the edge, and be certain that the adjuster mates solidly with the blade. Visually check that it’s centered in the throat.

Next, square the cutting edge in the mouth. First, get it roughly set by turning the plane sole up with the blade projecting beyond the sole. Sight down the sole of the plane from the front. Make lateral adjustments to the blade until it projects equally across its entire width.

Now retract the blade so that it doesn’t cut. Then begin pushing the plane across a piece of scrap and increase the depth of cut as you go. When you start to get a shaving, notice where the blade is cutting. If it’s making a square cut, the shaving will be the full width of the blade. If not, adjust the tang of the blade in the direction of the corner that isn’t cutting. Pinch your fingers around the plane and blade near the cutting edge to keep that end still. Loosen the hold-down and nudge the tang over. Tighten the hold-down. Test and adjust the blade until it’s right. Finally, set the mouth—if that’s possible on your plane—narrow for figured and hard woods and wider for soft woods.

Set Up for a Square Cut

A shoulder plane’s primary use is to trim joinery, so it’s critical that it take a shaving the full width of the blade and of a consistent depth. Here’s how to set the blade to get that job done.

|

| click to enlarge |

| Set the blade in the body. Pinch the blade between your fingers to center it, and tighten the hold-down to keep it in place. |

|

| click to enlarge |

| Then adjust the mouth, if that’s possible on your plane. |

|

| click to enlarge |

| Narrow shavings are bad. A blade that’s cutting square takes a shaving across its width. This blade is cutting too deep on the right. |

|

| click to enlarge |

| Here’s how to fix the problem. Loosen the hold-down just enough to allow you to shift the blade’s tang. Move it toward the side of the blade that wasn’t cutting. |

|

| click to enlarge |

| When the blade is cutting square, it cuts a full-width shaving that has a uniform thickness. |

Keep the Plane Vertical in Use

A simple bench hook holds workpieces on their side so you can hold the plane upright, where it is easier to control.

For Tenons, Keep the Pressure Even

|

| click to enlarge |

| First, place the toe of the plane on the tenon and slide it forward until the blade just touches. |

|

| click to enlarge |

| Then take a shaving, keeping even pressure on the plane throughout the cut. |

|

| click to enlarge |

| Start at the shoulder. And don’t overlap cuts. Otherwise, you’ll get cheeks that aren’t parallel. |

|

| click to enlarge |

| Keep it upright. For the wall parallel to the board’s face, clamp the board between benchdogs and use your off hand to keep the plane tight against the rabbet’s vertical wall. |

|

| click to enlarge |

| Use a vise for the other wall. With the board on edge, there’s no need to lay the plane on its side. |

Comments

Very informative and just what I needed to know to get working with my new Lie Nielsen shoulder plane !

Gee, and I thought it was a deeply guarded secret why the Lie Neilson shoulder plane blade is a smidge wider than the body of the plane. (a smidge is one tenth of a bit)

Log in or create an account to post a comment.

Sign up Log in