Milling Lumber

-

Mill your own woodturning blanks from “curbwood”November 21, 2023

Mill your own woodturning blanks from “curbwood”November 21, 2023 -

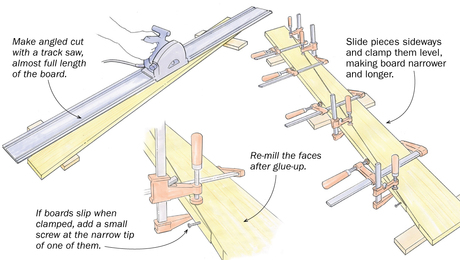

Fresh take on board-stretchingOctober 9, 2023

Fresh take on board-stretchingOctober 9, 2023 -

Bandsaw strategies for safe, straight cuts in solid stockFebruary 16, 2023

Bandsaw strategies for safe, straight cuts in solid stockFebruary 16, 2023 -

From the bench: Gift of lumber, gift of foodOctober 6, 2021

From the bench: Gift of lumber, gift of foodOctober 6, 2021 -

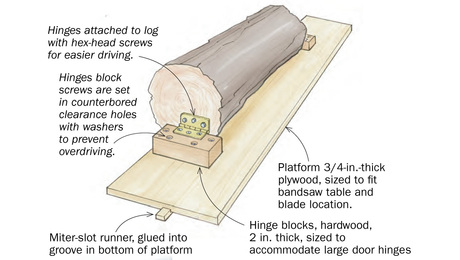

Workshop tip: Door hinges are the key to this log-milling jigAugust 26, 2021

Workshop tip: Door hinges are the key to this log-milling jigAugust 26, 2021 -

Handplaning With PrecisionDecember 22, 2020

Handplaning With PrecisionDecember 22, 2020 -

Turn Your Logs into LumberNovember 14, 2019

Turn Your Logs into LumberNovember 14, 2019 -

A Joiner’s Tool KitOctober 29, 2019

A Joiner’s Tool KitOctober 29, 2019 -

Milling Your Own LumberOctober 29, 2019

-

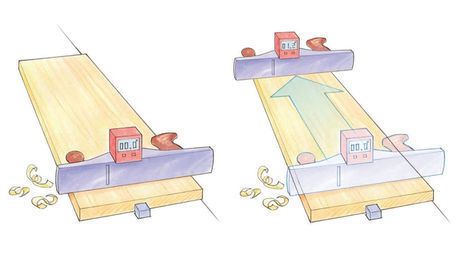

Workshop Tip: Use a Digital Angle Cube in Place of Winding SticksAugust 22, 2019

Workshop Tip: Use a Digital Angle Cube in Place of Winding SticksAugust 22, 2019