Six-Inch Jointers, Head to Head

Priced from $325 to $1,600, these 10 machines are aimed at home or professional shops

Synopsis: If you’re having trouble getting tight joints, square corners, and flat surfaces, chances are you’re either having a jointer problem or you’re without a jointer, writes Charley Robinson. He explains a jointer’s attributes and talks about the trade-offs of selecting various sizes of machine. He looks at ten 6-in. machines and compares them for assembly, adjustment, cutterheads and knives, fence mechanisms, motors, drive trains, and overall performance. He explains how they work and how to adjust them effectively. You’ll find out if more money buys a better machine.

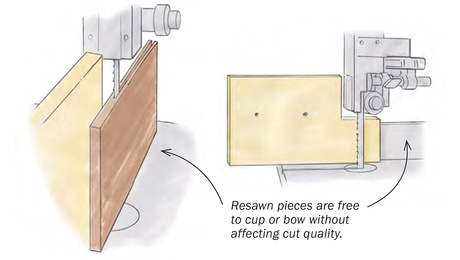

If you have trouble getting tight joints, square corners and flat surfaces, chances are you’re either having a jointer problem or you’re without a jointer. A jointer establishes the reference surfaces from which all other machining is done. And in addition to truing edges and removing cup, bow and twist, jointers can taper, bevel, chamfer and rabbet (see the photo above).

These attributes help make the jointer one of the most useful tools in the workshop and one worth choosing very carefully. Jointers are sized by the length of their knives, which translates into the widest board they can face joint. Generally, the bigger the machine, both in length and width, the easier your woodworking will be. With a wider machine, you won’t have to rip boards as often for face-jointing and, consequently, you will have fewer gluelines in panels and tabletops. Longer jointer tables (also called beds) provide better support for boards entering and exiting the cutterhead, resulting in straighter stock.

The trade-offs with a big machine are the amount of floor space it takes up and its cost. There are many other factors to consider, too, such as design, availability of parts and service, and ease of use. Some of the imported jointers are a lot alike (see the three jointers stacked up on p. 84). After you examine the castings and motors on several machines, you’ll be convinced that they were and are more expensive. From the field of 6-in. jointers, I picked 10 of the most popular brands, including Powermatic, Delta, General and a generous sampling of Taiwanese models. I chose machines that are stand-mounted with an overall table length of at least 40 in. (less than that, I think, makes it difficult to get accurate results). List prices ranged from $329 to $1,593. Many companies offer more than one 6-in. jointer, so I asked each for its best model. Bridgewood (sold by Wilke Machinery) has two models. Because the better machine was out of stock, I included the less expensive one. The only differences are in the stand and in the fence.

I’m aware of a half-dozen other companies that also carry 6-in. jointers.

From Fine Woodworking #115

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in