Video Tour: Garage Shop Makeover

Join Mike Pekovich as he takes you through the shop's principal elements in this video workshop tour.

Fine Woodworking art director Michael Pekovich’s total garage shop makeover proved so popular when we debuted it in the blogs this past September, we had to return for a second look. Join Mike as he takes you through the shop’s principal elements in this video workshop tour.

Plus, be sure to catch the companion article for all the structural details. Mike takes you through every step of the process including:

Plus, be sure to catch the companion article for all the structural details. Mike takes you through every step of the process including:

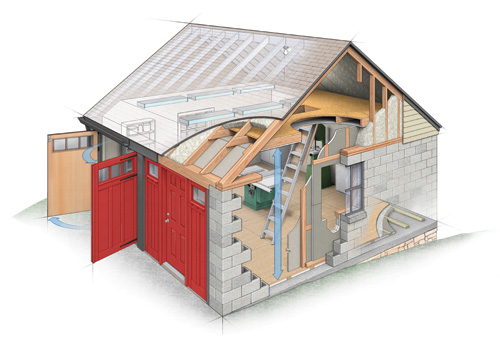

• Installing new doors

• Adding a wood floor

• Finishing the ceiling

• Insulating the walls

| More on Building Your Dream Shop • Total Garage Shop Makeover • Set Up Shop on a Budget • Fine Woodworking Shop Tours • Tour the Ultimate Garage Shop • Wiring a Garage Shop • Dream Shop in the Woods |

Comments

Great light and layout of machines. I especially like the table saw outfeed table.

The articles were very interesting, but the video makes the changes much more clear... particularly on the quick walk around the fixed machines.

Two questions from me -

How do you exchange air with the attic ceiling sealed?

Where did you put your cars?

Someday, I would like to see a collection of basement bodge shops like mine, with sawdust and rusty pipe clamps.

Hi Anji12305, With the insulation applied to the underside of the roof, there's no need to vent the attic space. This is referred to as a "hot roof" system. As far as the cars go, they've always lived in the driveway. The snow is easy to sweep off, but the ice can be a problem...

-Mike

Looks very nice Mike. It often seems that building the shop is seemingly much more enjoyable than building furniture. Enjoy your new home!

nice article. why poplar and not 2x pine?

Hi jerrin- For the doors, I started with 8/4 poplar and milled it to 1 1/2 thick. I wanted to make sure the stock for the door frame was really square and flat so the finished doors would be flat as well.

-Mike

Mike,

Thanks for inviting us into your shop! The awesome 15 drawer storage cabinet you showed us, is that your design or out of a book?

Regards

Paul

Anyone can re-org their garage space, but the cabinetry makes this one work! That 15-drawer cabinet is awesome.

Mike - was your original concrete floor sloped? Modern garages have a slope - required by code. Mine slopes all the way to the back, but it was well done and is smooth. I've got about 1000 sf - big job to cover it and level it. (I've got 8 foot doors and over 9 feet to the ceiling)

Do you open that window behind the chop saw when you run it?

It will be years before I can do cabinets like that. Sigh.

Your shop & how it's presented in the video is an absolute home run....many thanks..

GPDC

Very nice! Great use of limited space. But, a "hot roof system"? Never heard of it. The video does not show the roof of the garage/shop- if it's a shingle roof, how will you keep the shingles from 'baking off' and curling in a few years? If it is a proven system I would do the same to my garage...

Great video Mike, Ed. The transitions (entry door, attic door)are fun.

Hi riant- I went with the spray insulation on the advice of my insulation contractor. There's some internet debate about the process, but it seems to be an accepted industry practice. Here's a good explanation:

http://www.airtightinsulationpa.com/Applications/NonVentedHotRoofSystem/tabid/185/Default.aspx

Moshup Trail- There may be a slight slope to the pad, but it's not noticeable. I honestly didn't think to check before I laid the floor down.

-Mike

Nice but where is your wood stored. My biggest problem is wood storage. I do a lot of small projects and have a hard time tossing even the smallest piece away.

Nice shop!

One thing that rarely gets mentioned in these shop articles (or in FWW's "Setting Up Shop" book) is sharing space with other interests. Our garage is wood shop, car shop, and storage space for a variety of outdoor gear. I would love to see ideas others have regarding maximizing space for disparate interests.

Thanks!

Nice work Mike. Really nice shop. Excellent use of space and wonderful storage units. This is exactly what I was hoping to see in Fine Woodworking. A real life, doable, shop concept that is functional, practical, well designed and organized, great layout, with methods and ideas I can relate to and utilize.

Any chance for future storage unit plans in FW? The hot roof is a good idea. I have a 2.5 car garage with an uninsulated, similar attic. Had not thought about spray foam and a hot roof. A lot easier than fiberglass.

Is the 6 mil vapor barrier on top of the purlins between the plywood floor and the foam/purlins, or on top of the concrete between the purlins and the concrete?

Thank you,

RandallS

You have a lot of equipment in a small area but I did not see a dust extraction system for the bandsaw or tablesaw. The jointer/planer is vented but no vacuum collection system is obvious. With such an air tight setup, I would be choking in sawdust from the unvented equipment or sanding in a short time. Cleanup of dust from the top of equipment and floor would be a time consuming maintence requirement.

this video made me laugh. my current w'shop is the the front of a 2 car garage not occupied by cars . of course the cars can be moved but all eq'ment has to fit in this space. to have the whole space wd be the ultimate luxury. maybe you shd do an article on really small w'shops. i am 74 and despite the restrictions i have produced the following items over the last few yrs :drop leaf table; lift-top occasional table; nest of tables; hall table; 6ft buffet; two level auto-tray( tea trolley) with drawer. i have also converted an old piano to a desk and computer centre.

RandallS- Thanks for the nice comments. We do have some shop storage ideas in the works- stay tuned!

The vapor barrier goes on top of the 2x4s and insulation because I glued and nailed the 2x4s to the concrete. I used pressure treated studs in case there was any moisture build up below the vapor barrier in the future.

fransel- You're right to be concerned about dust collection. It's one area of my shop I still want to improve on. I have a small collector that I hook up to my planer and bandsaw. The chips from the jointer fall into a box. I'm not in a hurry to hook it up to dust collection because I don't think it creates a lot of hazardous dust. I could be wrong. My old table saw needs some serious modifications before I can hook it up to dust collection. I use hand planes when ever possible and wear a dust mask when I have to sand. I'm leaning towards a ceiling-mounted filter to clear up the dust I can't capture at the source. Gone are the days when I'd boast that my only dust collection was a broom and dust pan. The risks of wood dust are just too well documented to ignore them.

Nice layout but, where do you put you projects while you are constructing them? I did not see anywhere that you could assembly a large book case or chest of drawers let alone finis them? My shop is perfect until I want to assemble a piece.

Nice lay out. It looks like one wall needs either cabinets, shelves, or both, though, as it looked pretty empty.

Mike said: “As far as the cars go, they've always lived in the driveway. The snow is easy to sweep off, but the ice can be a problem...”

How about a folding garage? No, I'm not from the UK. Just an idea.

http://www.canopiessouthwest.co.uk/car_ports_perambulator.html

By the way, I’m curious about the foam spray. Is it open or closed cell foam?

Nice shop. Wow! Lots of drawers. Maybe your memory is better than mine, but how do you remember what's in each drawer? It doesn't look "pretty" but I built something on the front of my drawers (like a picture frame without the top) and I can put paper cards in them. On these cards I can write with pencil and show what's in the drawer. If I remove something from the drawer I can erase the name. I can also add names when new things go in the drawer or I can adjust the list if necessary.

Dear Mike, I was just looking at your striking garage conversion in my husband's issue of your magazine and I have what is probably a bit of a "girly" question. Would you happen to have the brand and name of the red paint you used for the doors? It's a great color and would be perfect for my husband's new shop (though of course he doesn't know this yet). Many thanks.

thewife- I'm an art director by day, so I don't consider it a girly question. The doors are painted with Behr Ultra Exterior Satin Enamel. My daughter picked out the color- Red Pepper UL120-22.

Good luck, Mike

I love the carriage door idea and might just steal it since my garage has never, and will never, hold a car and the overhead door tracks drive me crazy. Quick question: where did you purchase the strap hinges? LV has some for ~$25 per hinge which adds up too quickly for my budget @ 6 hinges per bay. Are you able to make a recommendation here?

Thanks a ton

I bought my hinges from hardwaresource.com-

http://www.hardwaresource.com/hinges/GATE+HINGES+AND+HARDWARE/Gate+Strap+Hinges/Strap+Hinges%2C+Bean+Style%2C+Heavy+Duty

They're about $32 a piece, so the Rockler hinges might not be a bad way to go. Butt hinges would be a cheaper option if you want to go through the work of mortising them.

-Mike

I really like the design of the doors and will be starting to build similar ones after the holidays. The lines are pleasant to look at. What are the dimensions of the stock you used for the frames? I understand it is 1-1/2" thick but what is the width of the boards?

Thank you and I really enjoyed the article.

The width of the internal door frame is 4 1/2 inches. The width of the trim boards on the outside face of the door vary. The outside vertical pieces and top piece are 4 1/2 inches wide. The center vertical pieces are 3 inches wide and the bottom is 6 inches wide.

Good luck, Mike

Mike, thanks for your article in the Tools & Shops annual issue. The timing was perfect. I am building a new shop and like you I wanted Carriage House doors but could not find any for an affordable price. I copied your doors and I now have a pair of great looking doors on my shop. I am curious about one item not mentioned; your outside light. The light looks great with the style of the doors. Can you tell me where your lite is from? I've looked at many lights but have found nothing like yours.

Thanks again Mike.

Olnook.

Olnook- I got lucky and found the light fixture at Home Depot. It was the only motion-sensing light that was even close to the look of the garage. I know I don't have the paper work anymore, but I'll see if I can at least get a brand name for you.

-Mike

Nice job Mike! One question concerning the wood doors. Did you seal the raw edges and top with anything special like West system epoxy or just a good primer?

Thanks in advance

I didn't seal the door edges with epoxy, though that's probably not a bad idea. When gluing, I made sure I had squeeze-out all along the edges and I sealed the door with primer before painting. They survived their first winter without any problems. -Mike

Thanks mike for sharing!!

I'm currently am setting up my shop and found this shop tour very helpful. I really like the setup for the jointer,planer,tablesaw.

Thanks!!

Matthew Kanomata

Hi Mike, like the video and nice job on the shop.

How do you heat the garage? What system do you use?

Thanks

I use a wall mounted 25000 BTU direct-vent propane heater to heat the shop. I keep the shop heated to a minimum of 55 degrees throughout the winter (I kick it up when I'm finishing). I have a 100 gallon tank and I go through about 1-1/2 tanks a year.

MIke

why poplar wood for the big frames?

more stable im sure..

was the width of the poplar 31/2 inches ?

wood threshold for the big doors , with just basic sweeps ?

What are the dimensions of the shop?

20x20 I believe

It'll soon be 10 years since this video came out. Is a shop update coming soon? I hope so!

That's a good idea.

Ben, do you per chance know the source of Mike’s comment on sq. ft vs. cubic ft? He mentions reading it in a workshop book, and I’d like to explore that idea more fully for my own shop setup. If not, no worries. Thought it worth asking, either way.

Hi Mike! Great project. I'm building something similar and was wondering which strap hinges you used? I'm having a devil of a time finding the right set.

“[Deleted]”

Log in or create an account to post a comment.

Sign up Log in