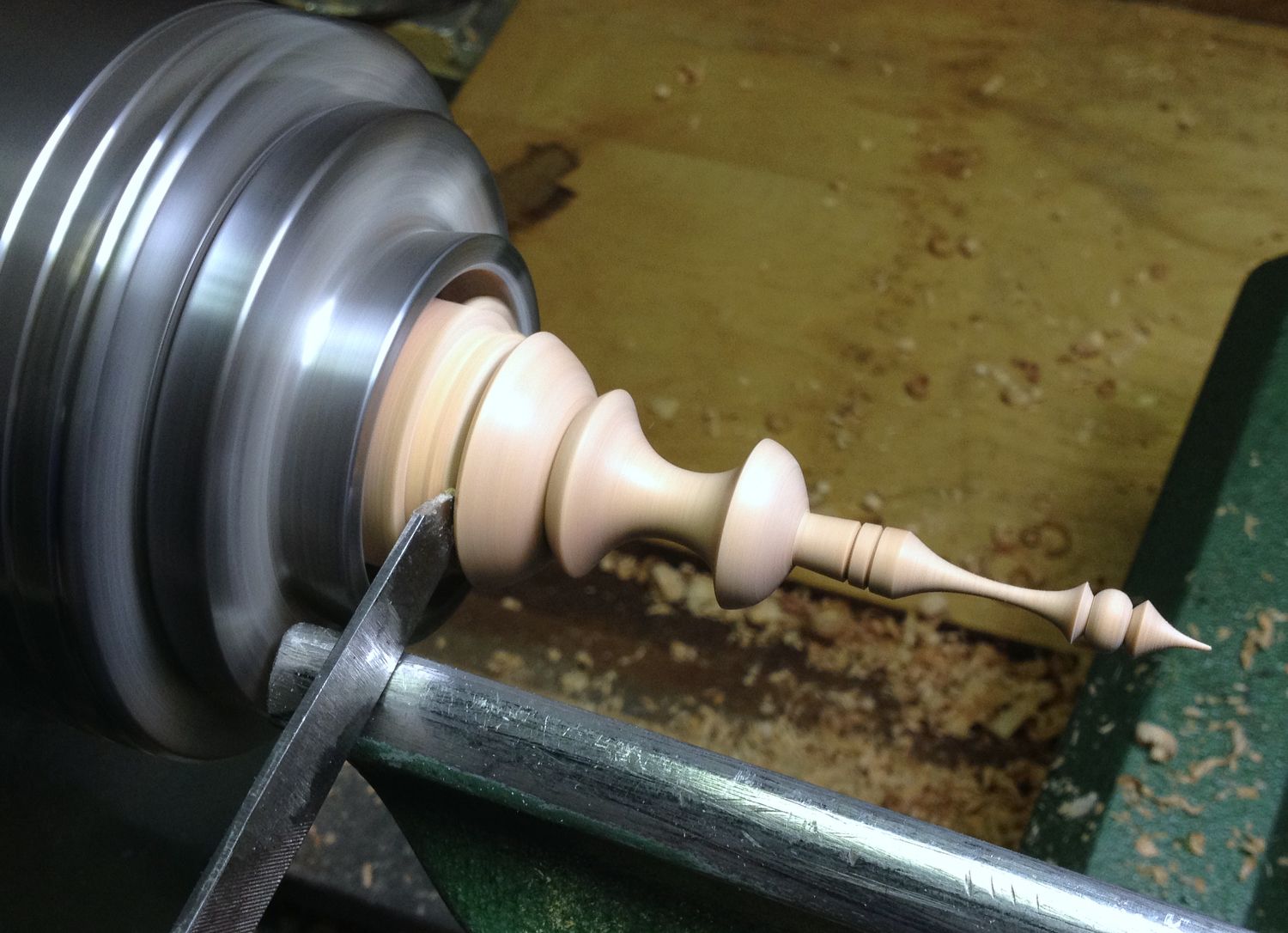

Grip Smaller Work with the Standard Jaws of Your 4-Jaw Chuck

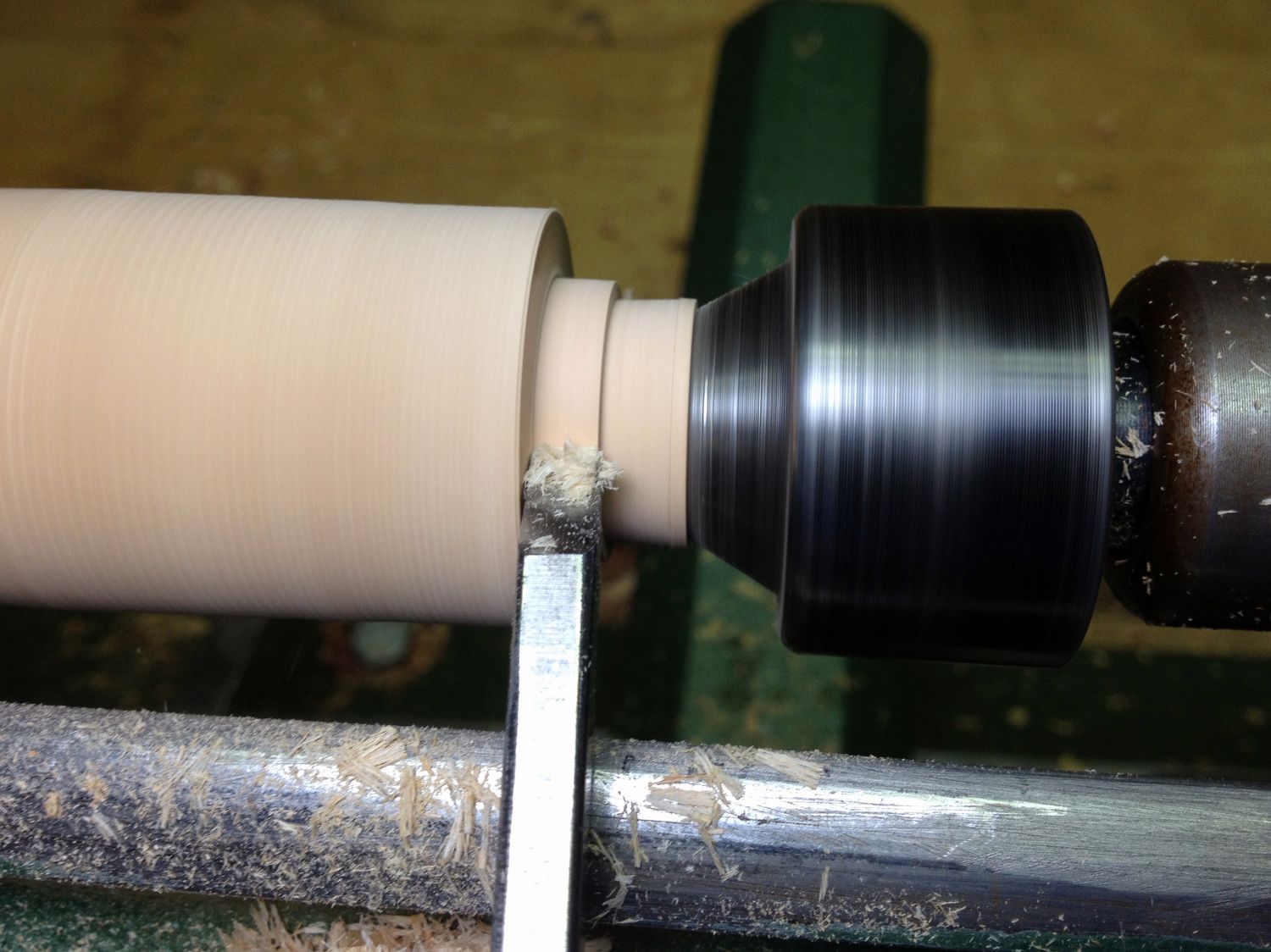

The inner portion of a standard jaw set is a great place to grip a tenon on smaller work.

A lot of my spindle work is turned from 1 ½ inch and smaller stock, and my 4-jaw chuck came with the “standard” jaws that can grip a tenon down to a diameter of about 1 5/8 of an inch. I wasn’t thrilled with the hassle of changing jaws, but I finally decided to drop $50 for a smaller set.

A built-in set of miniature jaws.

When I started to remove the screws, I realized the small circular relief of each jaw quadrant could grip a smaller tenon and make a great “mini” set of jaws (see photo). The “real” jaws block access by about a ½ inch, but I reasoned that was a small price to pay for the convenience!

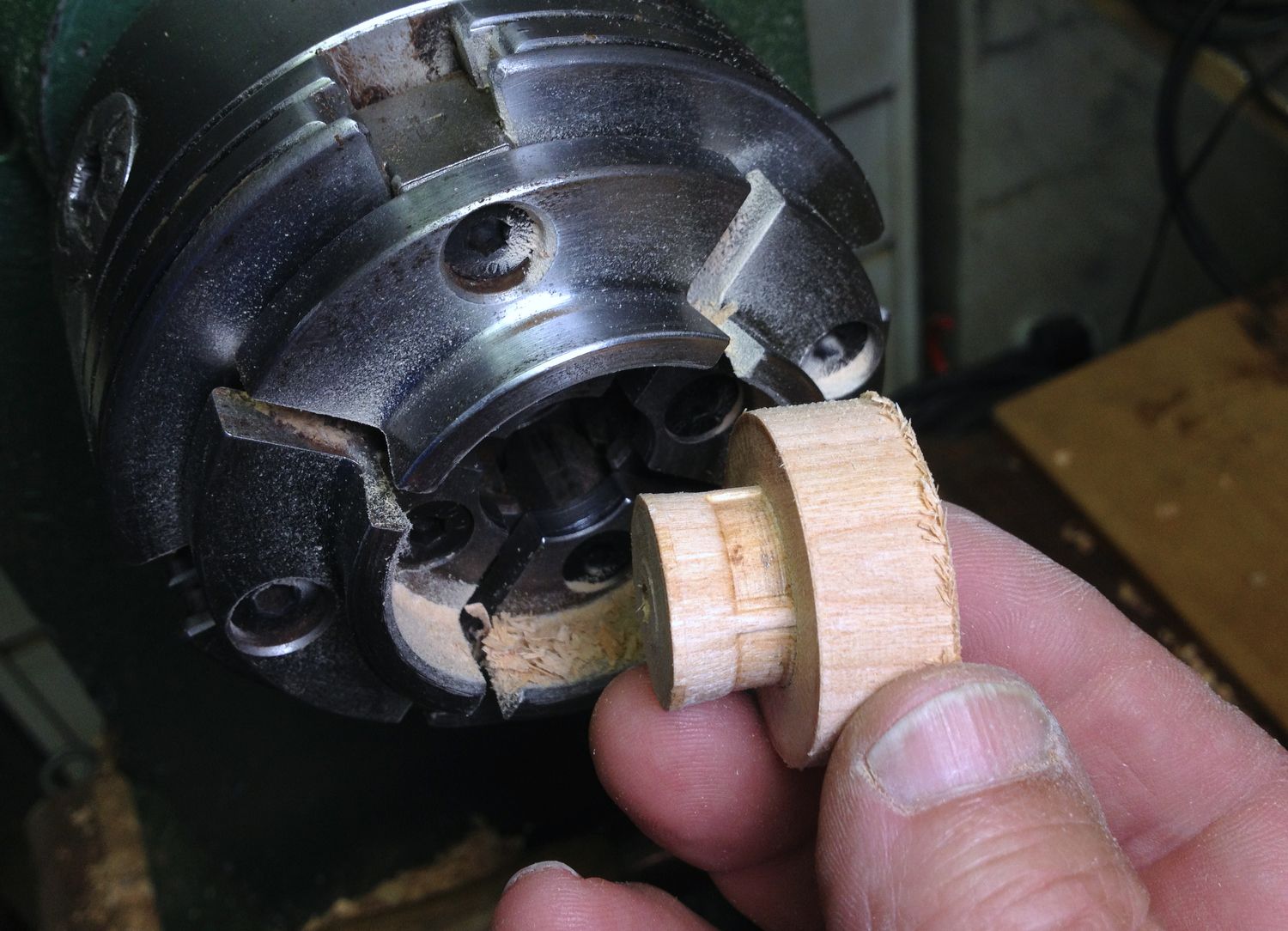

Sizing the blank.

Measure the diameter of the hole in the chuck’s main body and be sure to turn the tenon smaller to avoid interference. I turn mine to just under 1 inch. Be sure the tenon is shaped with parallel sides or a very slight taper, and cut the shoulder at a right angle to provide secondary support along the interior portion of the jaws. Obviously the blank’s diameter has to be under 1 5/8 of an inch and be aware that if you start with square stock, the corners should be removed to avoid making contact with the main jaws.

Use caution when parting off.

When parting off, be sure to position the toolrest to avoid a gap between the front of the jaws and the edge of the rest. The deep indentations on the tenon is proof of the gripping power, and the shoulder support from the large flat portion of the jaws allows more than adequate holding for smaller spindles.

Comments

When turning small bowls or boxes, I turn the box around and use the out side edge of the jaws to grip the box's mouth so I can clean up the bottom.

Good point Butch, I usually grip a tenon, but the jaws can also expand to hold work.

Log in or create an account to post a comment.

Sign up Log in