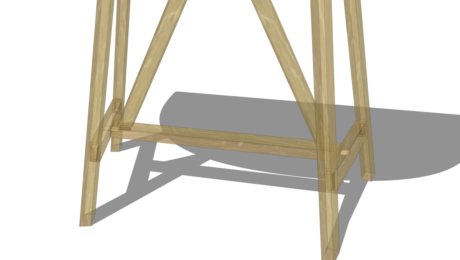

Table Saw Tapering Jig is Safer and Faster

Learn how an adjustable leg tapering jig can easily cut two, three, and four-sided tapers on the tablesaw

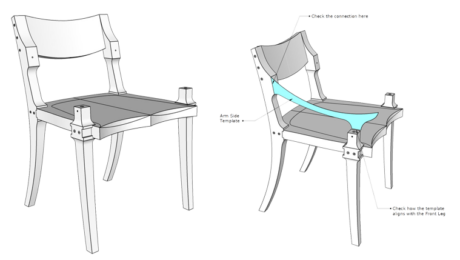

Tapered legs are an easy way to refine the appearance of tables and chairs, but most commercially available table saw tapering jigs can be a bit questionable when it comes to safety. The most common type consists of two aluminum sections hinged on one end, but because the workpiece isn’t clamped to the jig, the operator’s fingers are forced to come dangerously close to the spinning blade.

Furniture maker Steve Latta’s solution was to build a custom sled that not only holds the workpiece securely, but which rides along a custom-made L-guide that clamps to his tablesaw’s rip fence. This allows the user to back the sled out of each cut entirely, without having to worry about the jig assembly tipping off the tablesaw. In this way, the user can make a cut, back the sled out, reposition the leg, and make the next cut, all without having to turn the saw off or worry about the stability of the sled poised on the edge of the tablesaw. Overall, this table saw tapering jig is fast, safe, and easy to make yourself from materials you might just have laying around.

Additional Reading:

- Crosscutting Tapered Legs on the Radial Arm Saw

- Video Workshop Episode: Tapered Legs

- Video: Shaping Tapered Legs by Hand

- Cutting Stretchers for Tapered Legs

Comments

This is an excellent example of simplicity in action. I am making a small side table, and looking for an easy (safe) way to cut tapered legs. Your jig meets all of those criteria and looks very easy to build. Thanks for demonstrating too. Just what I needed. Ross

I wish Latta had given more information on the moveable section of the jig. I am going to have to experiment with the width of the slot for the hold-down block and the width of the slots for the screws.

It would have been nice to have some dimensions to build this sled.

@user-666059, dimensions are given in the PDF here: https://www.finewoodworking.com/2012/09/27/perfect-tapers-on-the-tablesaw

Log in or create an account to post a comment.

Sign up Log in