Deinonychus Skull Carving

The completed jaw bone after a few coats of spray-on lacquer.

Bryan Way became interested in dinosaur fossils during his time studying geology in graduate school. While helping his school set up a Natural History Museum, he was able to handle and study the skeletons of numerous dinosaurs.

This fascination would inspire him later in life to build this scale carving of a Deinonychus skull with some leftover cedar and some spare time.

After hours of hands-on study and compiling dozens of full-sized photographs, Way began the carving process with the lower jaws. These were easier then the skull halves and gave him a good understanding of the tools and techniques he’d need during the rest of the work.

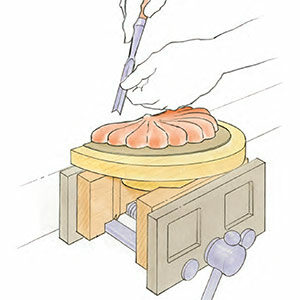

The jaw blanks were roughly cut on his band saw, then shaped with gouges, chisels, and even homemade micro-chisels created from piano wire and hex key wrenches.

Once the jaws were complete and Way’s skills were honed, he moved on to the main skull sections. After gluing up a solid block, he started by carving the eye sockets and moved on from there.

“One of the most difficult aspects of this part of was trying to go from two-dimensional photographs to a three-dimensional object,” stated Way. “The jaws were simple since they were much smaller and didn’t change much in shape, but the head was much more complex and often required me to make clay models of various parts.”

As with the jaws, everything was carved to form by hand. The two halves of the skull had to be both accurate and symmetrical to eachother. The final piece of the carving was the brain stem, which held the two halves of the skull together. The finalized skull measured 11 in. long and 4 in. at its widest point.

The finished components were then sanded and sprayed with several coats of lacquer to simulate the look and feel of fossilized bones. The base of the stand was carved from mahogany and the hardware was handmade from steel Way had in the garage.

“I lost count on how many hours I spent on this piece, but it was one of the most enjoyable projects I’ve ever built,” Way exclaims. “I hope this is not the last dinosaur skull I build.”

Comments

A very cool project, but the headline is incorrect. This is a paleontology project, not an archaeology project. Archaeology is specifically concerned with the products of human activity.

Wow really cool. That skull looks good enough to be in a museum.

Log in or create an account to post a comment.

Sign up Log in