Reclaimed Rocker – Part 1

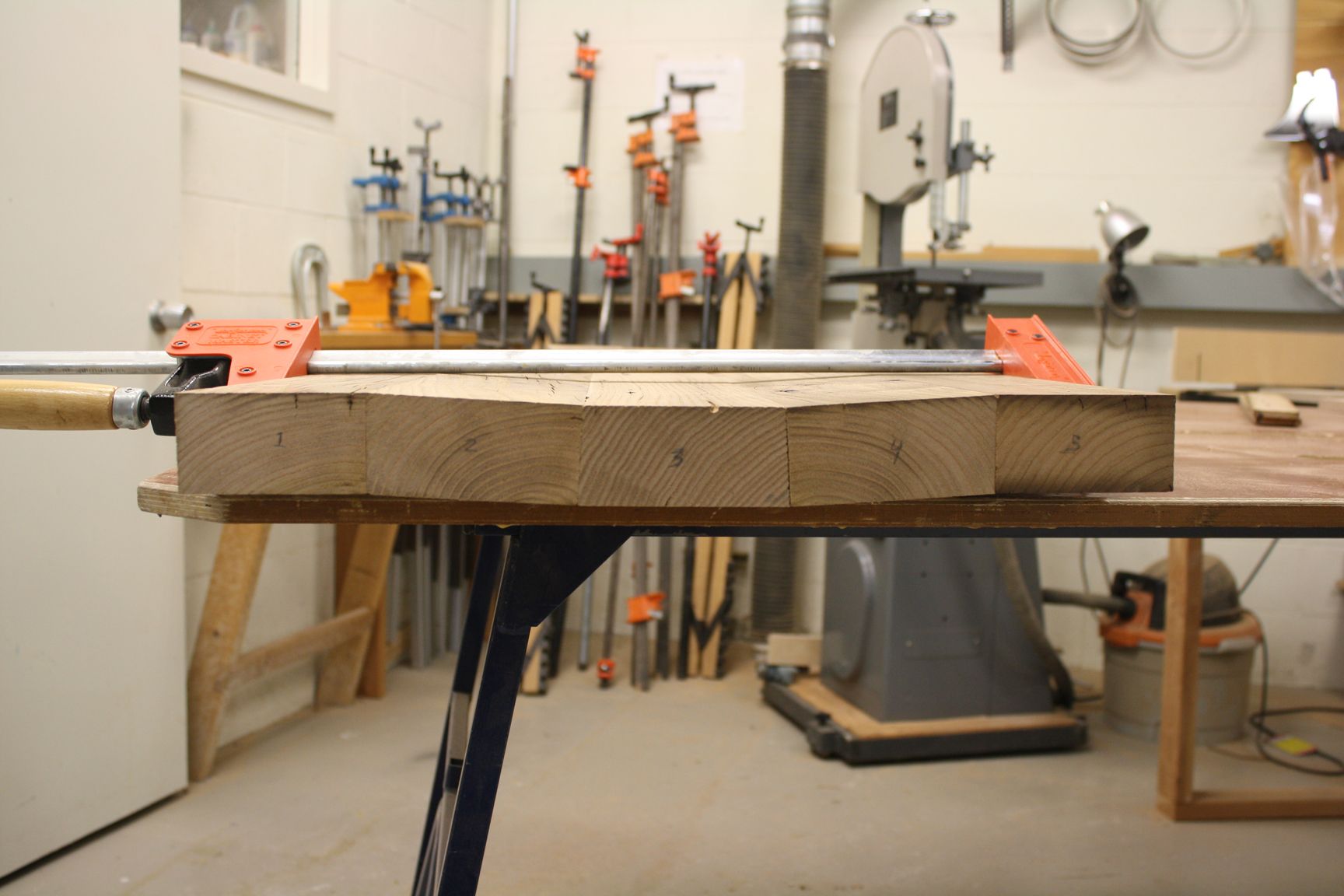

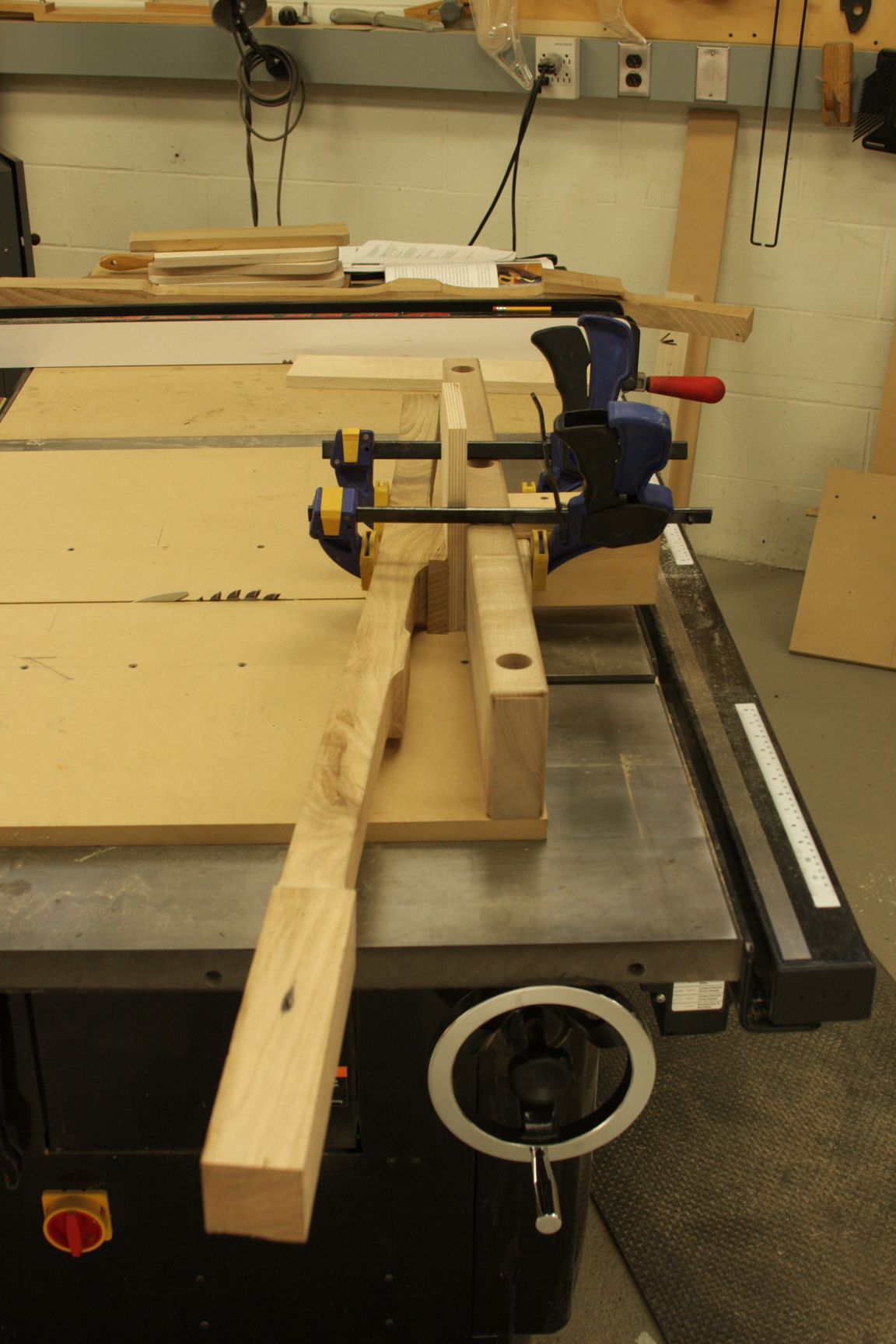

The first step is choosing the five boards that will make up the seat.

More on Maloof-Style Rocking Chairs

Reclaimed Rocker – Part 2

Sam Maloof on Building Chairs

How Sam Maloor Makes a Rocker

“Too often we design things and take all the credit for what we do, and if we have any kind of success we become very smug and conceited about it. I think that all one has to do is look at a beautiful flower or a tree and realize that what we do is very insignificant. We are only the instruments that make these beautiful objects.” – Sam Maloof

I’ve been drawn to Sam Maloof’s designs ever since I started woodworking. He found inspiration in nature and made countless beautiful forms out of wood. His rocker is one of my favorites.

For this project, I referenced an article by Sam Maloof way back in Fine Woodworking issue #42, “How I Make a Rocker”, as well as the book and dvd set “Build a Sculptured Rocker with Charles Brock”. Charles was kind enough to give our Editor, Asa, a copy of his book when they met at a woodworking themed Martha Stewart Show in New York. The book and dvd had helpful information, but is separated between the two. For me it was a bit tricky to reference back and forth as I worked. I ended up taking a few notes from the dvd and printing out Maloof’s article as well as a whole bunch of reference photos of Maloof’s work.

I decided to make two rockers at the same time, and all was going well with that plan as I made multiple parts. And then I started sculpting the first seat. It was just too much fun. I couldn’t stop sculpting and ended up continuing on with one chair from there.

Both chairs will be made from reclaimed American Chestnut. I used a few 2″ thick 1860 roof rafters from a dismantled barn, and a 3″ thick floor joist from a 1790 home. Follow along to watch the chairs take shape.

Log in or create an account to post a comment.

Sign up Log in