Cutting Bench Makes it easy to convert fresh-cut logs into turning blanks

Holding fresh cut logs securely and in the proper orientation is key to being safe when using a chainsaw to convert timber into bowl and spindle turning blanks, and I decided to build a dedicated bench for the purpose. I use this method with logs from about 8 to 18 inches in diameter. Very large logs are too heavy to hoist onto the bench and smaller ones are easier to cut with a bandsaw and a bandsaw sled.

Holding fresh cut logs securely and in the proper orientation is key to being safe when using a chainsaw to convert timber into bowl and spindle turning blanks, and I decided to build a dedicated bench for the purpose. I use this method with logs from about 8 to 18 inches in diameter. Very large logs are too heavy to hoist onto the bench and smaller ones are easier to cut with a bandsaw and a bandsaw sled.

Preparing the log

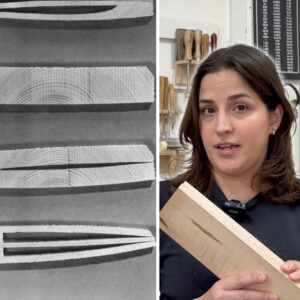

Whether cutting the logs for bowl blanks or spindle parts, the initial process is the same. Measure the diameter of the log, add 2 inches and cut the log to length. Just be sure this length is less than the length of your chainsaw bar. I then use a grease pencil to mark the cut-lines on the freshly exposed end. It’s tempting to cut into the endgrain of the log but it is much easier on the chainsaw (and the sawyer) to orient the log on the “round” and make the cuts along the log’s length. The problem with this orientation is the log is less stable and the use of a bench makes the job safe and easy.

Securing the log

The cutting bench should be sturdy and well built, and a good height would be equal to the length of you inseam and topped with a sacrificial piece of ½ inch exterior plywood. Note the section of the bench shaped like the letter “H”. This allows the cut portion to roll off away from the blade and avoids the chainsaw bar being pinched, which is a common occurrence when using the “X” profile of a conventional sawbuck. A unique feature of this bench is the cleat that acts as a stop and cutting guide, but most importantly it allows the use of 2 screws to secure the log and prevent it from rolling. The screws are driven into the endgrain of the log, in an area that will most likely become waste.

Sawing

I usually saw right through the center of the log, eliminating the pith and creating two half logs with flat surfaces. If necessary, I secure the half log to the cleat and use the chainsaw to make additional cuts along the layout lines. This method creates material with flat surfaces, making additional cuts on a bandsaw safer.

Using a Cutting Bench to Produce Bowl Blanks: Step by Step

Comments

Thanks for the helpful tips and video. Do you dry the bowl blanks or turn them green...and how do you prevent the wood from splitting as it dries?

Thanks Gpan, I either rough turn to a consistent but heavy wall thickness and slowly let the blank dry(it will turn oval), then remount to finish turn, or I turn the bowl green to a final thin wall thickness and I let it dry slowly. I hope to have more posts and videos showing the process. Joe

Good for green bowls, but I don't follow how you're going to get useable spindles from green wood. Cut these things and they're going to warp, check and probably just plain split apart. Nice bench, however.

Thanks; this does look like a huge help.

I don't have a chainsaw currently, and am sufficiently terrified of them that I won't consider getting/using one until I can get one of my friends who's an expert to train me... and even then I consider the kevlar chain-fouling chaps to be essential safety equipment, Just In Case. But I do know enough to understand that having the work level with your waist is going to be a LOT safer than trying to cut closer to the ground. I hadn't considered the idea of an outdoor workbench for the purpose, but it makes perfect sense!

I have a set of three trees due to be taken down soon, and I really can't bear the idea of all that wood going to waste, even if it is just poplar. Since this is suburbia the arborist will almost certainly want to take them down in chunks, so I'm not expecting to get longer boards out of them (sigh)... but mining the firewood pile for smaller pieces is a Fine Idea. I'd considered bandsaw (great excuse to upgrade from my small tabletop unit) and just going after it the traditional way with wedges and froes (poplar reportedly splits very easily), but this is an interesting approach to making the first rough cut -- akin to using a circ saw to roughcut plywood down to sizes easier to handle on the table saw.

More options is always a good thing!

Thanks Bob and Loxmyth , I haven't had any problems with warpage or splits when sawing out spindle blanks, as long as the growth rings were mostly concentric and I sawed in-line with the grain. Obviously the ends may check as moisture is lost from the end grain quicker than the cross grain, but a bit of sealer or cutting the blanks a bit longer is a solution. Of course, traditional woodworkers will still use wedges, froes and axes to split out blanks, but straight grain logs should yield you some good stock when sawing with the chainsaw.

I notice you saw through the pith and not cutting out the pith. What are your advantages to not sawing the pith out? Thanks for the idea of the sawing table.

Log in or create an account to post a comment.

Sign up Log in