Lessons From A Delivery Guy: Planning

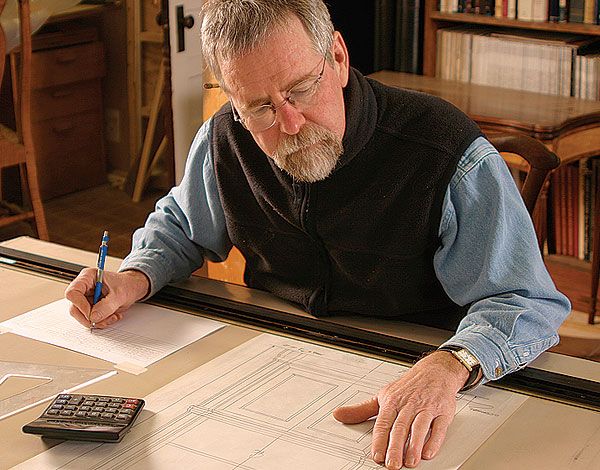

Avoid furniture-making disaster with tips from "delivery guy," John Broomall. Time spent planning can help prevent problems down the road.

Part two in our series on how to build durable furniture that will stand the test of time… and the trip to the client’s house: Lessons From A Delivery Guy.

Since delivery is part of the process that starts when you first envision a project, it pays to anticipate problems at the planning stage. We’ve all heard about the guy who built a piece that was too big to leave his shop. I’ve never met this guy, but I know lots of craftsmen who built a piece that would not fit into its new home, even if they won’t admit it. People buy furniture that won’t fit in their house all the time. One frustrated customer told me that, “Things would have been fine except for that lying yardstick.”

|

More from this series More on planning and design |

A quick walk through a furniture store will tell you what sizes generally fit into a home. But building your own piece means that you can create a design to whatever dimensions you like; it’s a blessing that can be a curse. You need to know that, no matter how precise you make your drawings, your piece will be inches larger in transit and that doors, halls and stairways are almost always smaller than you thought.

Protective blankets add two or three inches, and a dolly adds even more. Six feet turns into nine feet once you have someone carrying each end. That stair landing is large enough to hold the piece, but what about you, your helper, and the piece?

Doorways narrow once you consider storm doors, closers, openers, latches, locks, and knobs, let alone doors that don’t completely open. Seven feet of stairwell headroom sounds like plenty for a four foot piece but, because it’s really hard to go up stairs with your knees bent, you need to add your carrying height to the measurement. Other obstacles that narrow clearances include handrails, banisters, newel posts, stair winders, electrical fixtures including switches, interior steps, stairwell openings, baseboard radiators, and other interior fixtures. Don’t forget, you might have to deal with this stuff while walking backwards.

Planning from the outset means you will avoid one of the most feared questions in woodworking: “How will it look on the porch?”

Next time: Four perennial problem pieces

Any comments? Anyone out there build a piece too big to leave their shop?

Comments

My first commission was an eight foot tall, five foot wide bookcase to reside in the home office of a college professor. To get the whole thing through front of her small patio home and into her equally small office, I decided to make the bookcase in two 2.5’ by 8’ sections with a removable crown and base. This also made it easy to transport in my delivery truck which is really a Chevrolet Venture mini-van with all but the front row seats removed. I am just glad I thought to make the bookcase this way; otherwise it would have been really difficult navigating the small hallway leading to my client’s office.

A desk had to go through a door on the side of a hall and turn 90 degrees to enter the room, but the dolly made it too tall. We put it on its end on a movers blanket then dragged it down the hall, twisted through the door and tipped it back on its feet. Blankets will slide on hardwood and carpeted floors.

built a set of shop shelves, planning for removal from the basement. Planned the height of the stairwell, tipping to the side to get out of the switchback, and hand grips.

Fortunately I didn't put the top shelf to the top of the shelves (I used 2x4s). So the shelves could have been lowered simply by cutting the top 18" off.

All because I was 12 inches too long to take the stairs. (Measured the bottom of the staircase height, not the top. Turns out there was a 6 inch difference in the two heights.)

The dimension problem is something we see stationed in Japan all the time. Portions of walls or windows have to be removed often enough that it isn't a shock in order to get American furniture into Japanese homes. I'm excited to read your construction tips. Being in the military means moving often and military movers aren't the easiest on furniture - I am designing a china cabinet for my wife and am working out how to put in plywood blank-out plates for all the glass before the movers come...what else can be done?

Thanks for your service JV1997! Lately I have developed a real fondness for foam insulating board. It's available, inexpensive, easy to work, it can absorb a lot of impact, and it adds very little bulk or weight. You might consider using it on the tops or sides of pieces, it can prevent a lot of damage. The safest way to ship glass is removed from the piece, wrapped in bubble wrap, and shipped in its own padded box, preferably placed inside a larger piece. If you need to leave the glass in you might want to cover the entire front with foam and then put your plywood on top of that. If you happen to be around when they put on the blankets put a sign on it that says "GLASS" in as many languages as you need. Who knows, someone might read the message and give your piece some special care.

Log in or create an account to post a comment.

Sign up Log in