Easy-to-Make Plywood Drawers and Trays

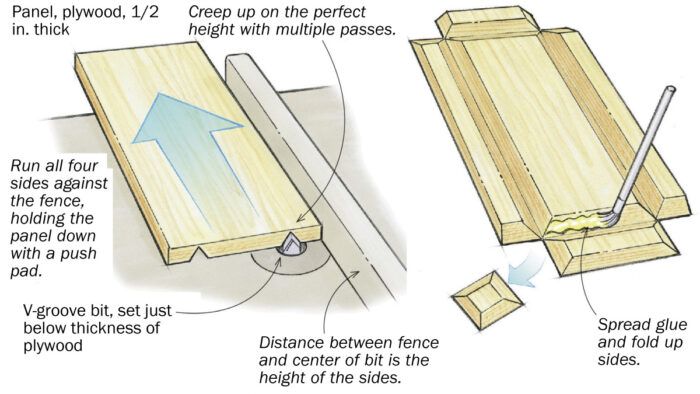

Rout V-grooves in a plywood panel and fold up the edges to form a box.

I needed a dozen small trays to hold hardware. I wanted them strong, but quick and easy to make. Then I remembered a technique Roy Underhill used on The Woodwright’s Shop years ago. He cut V-shaped grooves in a wood panel by hand, just short of breaking through the opposite side, and folded up the edges of the panel to form a box. I used a router fitted with a V-groove bit and traded the solid wood for plywood.

To size the initial panel, start with the length and width of the finished tray and add the height of the sides to all four edges. Then put the V-groove bit in the router and set the fence so that the distance to the point of the bit is the height of the box sides. Simply run all four panel edges against the fence. Do the first box in multiple passes, creeping up to the perfect depth of cut for easy folding without breaking. You can make multiple boxes with the same setup, as long as you use plywood from the same panel.

Use a sharp knife to remove the squares at the corners. Then spread glue in the grooves and fold the sides up to meet each other. I use blue tape to hold the sides together while I put a band clamp around them and tighten it. To avoid getting breakage at the folds, cover the back of the V-grooves with blue tape before folding them.

—JOHN BURKE, Northfield, N.J.

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Festool DF 500 Q-Set Domino Joiner

Veritas Precision Square

Comments

That is a neat idea. I only wish I read this 2 weeks ago when I started on a dozen trays I am building for my wife who is giving them as gifts.

Note in magazine promises "On line Extra". Watch editor Tom Mckenna bring this Workshop Tip to life in a video. Where is the video...? post a link please.

We're still working on it actually. We had a snafu ordering the bit.

So like where is this bit coming from, the moon?

Let's see this tip.

Thanks

Eric

Murray December 16

As mentioned above I am looking for the video promised in the magazine under "online extra" page 14

The video is finally live. I take complete and utter blame for it folks.

https://www.finewoodworking.com/2016/12/16/easy-plywood-box-tray

The bits that I have are too shallow and leave a non-45 degree edge on part of the wood. What bit did y'all use? Thanks!

I used a freud #20108 that NOT did provide proper 45 degree angles using 3/4 or 1/2 wood. Although the concept works, my router bit just did not have the proper wide angle. Thus, I'm in the market for a wide angle 45 bit that can have the depth to penetrate 3/4 stock

For 3/4" stock you're going to need a bit that is 1—1/2" wide. Good luck finding that monster!

Marco Levy: I bought the same one yesterday and it didn't work on 1/2" nominal ply. According to the package, The 45 degree portion is supposed to be 1/2" deep before the straight sides of the bit begin. NOT true. Still looking for the bit used in this tip. Someone help, please.

This is the bit we used in the video:

https://www.amazon.com/gp/product/B00004T7E5/ref=oh_aui_detailpage_o04_s00?ie=UTF8&psc=1

FOUND IT! Freud 20-116. Carbide length is 1", so this should do 1/2" ply easily. Here's the link: http://www.freudtools.com/products/product/20-116 I'll let y'all know how it goes.

I have made some boxes with the v groove bit and it works very well in 1/2 plywood.

So I wanted some made out of something thinner and with the same bit it will also do 1/4 plywood.

Jeff

This is a nice alternative to the expensive bit and jig set sold by one of the major woodwork supply companies that yields the same result. However both of these approaches leave me with the same question: How can this method yield strong joints when it results in 100% end grain glue joints.?

Log in or create an account to post a comment.

Sign up Log in