Looking Back: The Era of Manmade Machines

A generation of woodworkers overcame the high cost of machinery by building their own

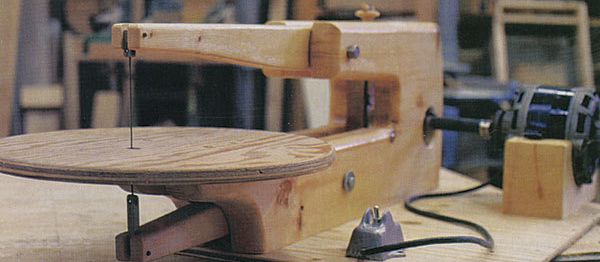

A look back at some of the fascinating shopmade machinery throughout the history of Fine Woodworking, from wooden tablesaws to bandsaws, planers, and more.

Read the original articles that inspired our contributors:

(available for a limited time)

| • Shopmade Bandsaw | • Mortising Machine |

| • Wooden Jointer | • Shop-Built Thickness Sander |

| • A Wooden Tablesaw | • Shopmade Scroll Saw |

| • Shopmade Lathes |

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in