Curved doors, simplified

Veneer over solid staves is the key to success

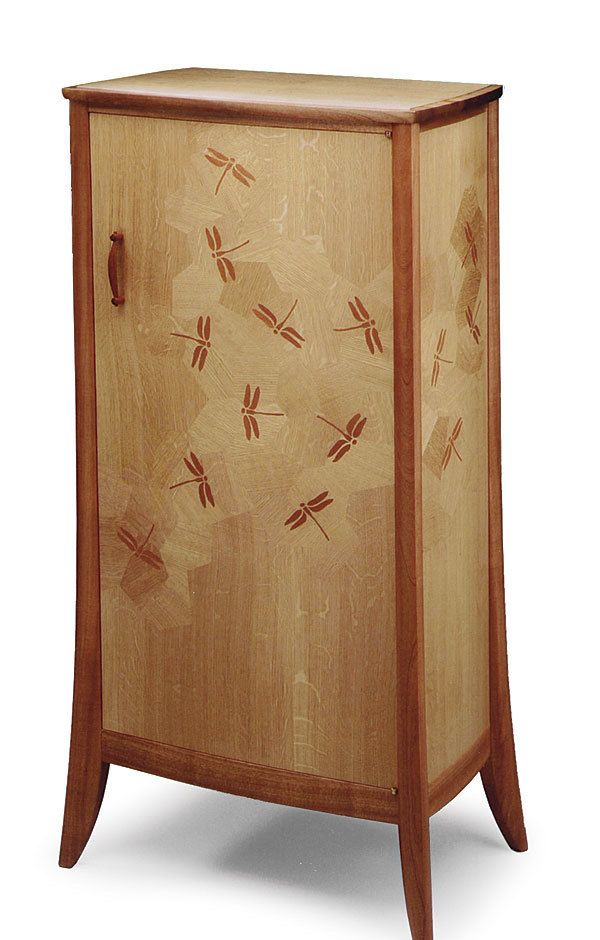

Synopsis: Tim Coleman makes curved doors using a shopmade solid-wood core sandwiched between veneers. The first layer of veneer on both sides is oriented perpendicular to the core’s grain, which effectively restricts movement of the staves and creates a stable panel. The assembly is edged with solid wood. The process is relatively simple and can be adapted to any number of projects.

Much of my work consists of veneered surfaces. As a substrate for flat panels, I use high-quality veneer-core plywood, but when I am working with curved or tapered surfaces, thick sheet goods don’t fit the bill.

In the past I have bent multiple layers of thin flexible plywood or resawn veneer over a form to create a substrate. But I often had a difficult time keeping the finished panels from distorting. With close-fitting cabinet doors, even a slight twist is quite noticeable. I am always open to new techniques, but it was an old one—and a step back in history—that led me to an alternative method.

In 2011 I had a commission to re-create two large tables for a Frank Lloyd Wright house. The original tabletops were veneered over a lumber-core substrate, with a thick, mitered solid-wood edge around the perimeter. You’d think that any movement across the width of the top would have broken apart the miter. But on this 100-year-old table, the miters were as tight as the day they were assembled.

This experience convinced me of the stability of lumber-core plywood, and led me to think about the possibilities of using it in my own work. I realized that a solid-wood core could be cut and shaped to suit a variety of curved and tapered forms, and I have since used it successfully on numerous projects.

Here I’ll illustrate how I make curved doors using shopmade lumber-core plywood. The process is relatively simple, and because only the front of the door is curved, the jobs of fitting and installing hinges are no more difficult than on a flat door. Lumber-core plywood with a twist Coleman’s curved-front doors feature a solidwood core sandwiched between veneers. The first layer of veneer on both sides is oriented perpendicular to the core’s grain, which effectively restricts movement of the staves and creates a stable panel. The assembly is edged with solid wood.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Compass

Log in or create an account to post a comment.

Sign up Log in