Small Clamps Everybody Needs

We put dozens to the test, but only 7 emerged as must-haves for woodworkers

Synopsis: A good collection of small clamps is essential to a well-equipped workshop. Your 48-in.-long clamps may sit on the shelf collecting dust, but your small clamps will never have the chance. Tom Begnal uses a variety of small clamps to cover the common small woodworking tasks, but he wanted to explore the many types he hadn’t used. So he gathered about 40 different models in the shop, and set about using each one in a variety of common woodworking applications. The clamps he found the most useful fall into five general categories: spring clamps, bar clamps, cam clamps, one-handed bar clamps, C-clamps, and hand screws. He tested several sizes and models in each category.

A good collection of small clamps is invaluable in the workshop. As my 48-in.-long clamps collect dust, an array of small clamps make a seemingly endless number of visits to my bench.

The ideal small clamp, I suppose, would work perfectly in every imaginable application. That means it would open and close quickly, tighten just as easily, and provide adequate pressure. The jaws wouldn’t dent or stain the workpieces. Clamping pressure wouldn’t cause the workpieces to shift. It would clamp non-parallel surfaces. And it would release pressure easily.

I’ve yet to find that mythical clamp. Like most of you, I’ve used several different types to cover the common woodworking tasks. But there were many I hadn’t tried. With that in mind, I recently took a close look at the growing array of small clamps on the market.

All told, I gathered about 40 models in the Fine Woodworking shop. Then I set about using each one in a variety of common woodworking applications. I tested several sizes and models in each clamp category. Once the glue had set and the dust had settled, I ended up with seven essential clamps.

By the way, a small clamp— at least according to my definition—has a maximum jaw opening of 6 in. Because I focused on the most common woodworking applications, this article doesn’t cover lesserused, specialty clamps such as toggle clamps, miter-joint clamps, deep-throat clamps, and the like.

Bar clamps are the workhorse

Small bar clamps get their name from the sturdy steel bar that runs the length of the clamp. They have two jaws: a fixed one at the end of the bar, and a sliding one that includes a threaded rod (typically an Acme thread) with a handle on one end.

Among all the various types of small clamps, the bar clamp has several advantages. It adjusts quickly and easily. Plus, it provides plenty of clamping force, around 760 lb. in our test.

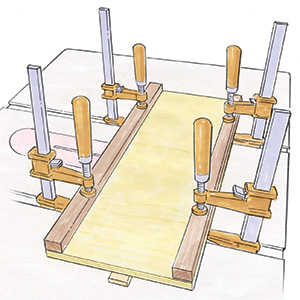

For those reasons, I reach for a short bar clamp more than any other small clamp. It is ideal for applying side pressure to open mortise-and-tenon joints (also called slip joints or bridle joints). For bigger edge-gluing jobs, like making a tabletop, I’ll use short bar clamps to squeeze the ends of clamping cauls and the ends of boards at the glueline. When gluing bent laminations, woodworkers take advantage of the bar clamp’s wide capacity, quick adjustment, and substantial clamping force. And I could easily list a few dozen more places where a short bar clamp gets good use.

From Fine Woodworking #199

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in