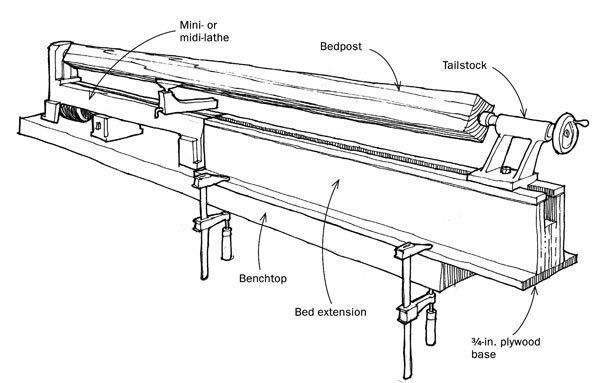

Low-Cost Bed Extension for a Small Lathe

To turn bedposts, you need a long-bed lathe-an expensive tool that uses lots of floor space. For less than $100, I made this bed extension for my midi-lathe. When not in use, the extension comes off and I store the midi-lathe out of the way.

Before building the extension, there are some design parameters to consider. The rails must be dense enough to handle the clamping force of the tailstock and tool rest. Also, the lathe must have enough power to handle the longer, heavier stock and the torque of working at the far end.

The extension has three parts: body, rails, and base. To build the body, laminate several pieces of plywood in a U-shape to match the cross section of your lathe. The number and size of the laminations will vary. (The sketch shows a cross section that fits my Jet Mini Lathe.)

Cut one end of the body at an angle to match the end of the lathe. The base is simply a piece of 3/4-in. plywood as long as the body. Leave 1 in. or so of extra width on the base so that you can clamp it to your bench.

For the rails, I used a lamination of hard maple and 1/8-in.-thick steel. Maple will reduce the vibration, and the steel will prevent the tailstock from compressing the wood. Fasten the rails to the body with wood screws. The assembled jig should match your lathe bed in height and cross section. To set up the extension, align the extension and the lathe with a straightedge and then clamp the extension to the bench.

Drawings by Jim Richey.

Drawings by Jim Richey.

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Forrest Woodworker II Blade

Rockler Dust Right 650 CFM

Log in or create an account to post a comment.

Sign up Log in