Finishing Boxes Inside and Out

Easy ways to protect the wood and line the interior

Synopsis: Small boxes are deceptively complex pieces of woodworking. All the pieces must fit precisely, with flawless surfaces inside and out. Finish is crucial when a box is made from several woods chosen for the beauty of their grain and color. Three woodworkers–Doug Stowe, Dave Shaw, and Emily Palm–share how they use two common types of finish with excellent results.

A box is a deceptively complex piece of woodworking. Small components must fit precisely. Surfaces inside and out must be as close to flawless as possible in order to withstand close scrutiny. There are lots of nooks and crannies where finish can pool. Also, one small box may be made from several woods chosen for their contrasting grain, color, or figure. So the choice of finish becomes critical.

Like many other woodworkers, boxmakers Doug Stowe and Dave Shaw experimented with different finishes until they settled on the one that works best for them. Stowe uses Danish oil. Shaw finishes his boxes mainly with hand-rubbed shellac.

The right finish for a box doesn’t always have to come from a can. A luxurious lining of suede cloth or velvet imparts its own special look and feel. Woodworker Emily Palm uses those fabrics in conjunction with wooden dividers to line her oiled hardwood boxes.

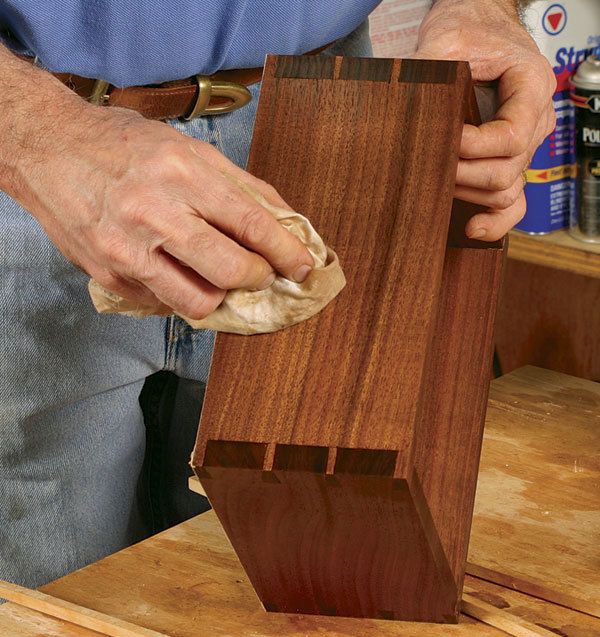

Danish oil: durable wipe-on finish

I finished my first boxes with Deft brush-on lacquer, but because I worked and finished in the same space, the fumes were horrid and dust settled on the surface. I started using Watco Danish Oil, but it never really looked like the wood had a finish. I tried Minwax Antique Oil, but I wasn’t happy with the smell.

When I discovered Deft Danish Oil, my problems were solved. Now I finish in the same room that I use to cut wood, and the odor is tolerable. The oil heightens the contrast between the local woods I use, making the inlay patterns more distinctive.

When designing a box, think about how and when you’ll finish it. In my experience, larger boxes or complex designs of any size should be broken down into their essential components and finished before assembly. But with small, simple box es, you can apply the oil after finish-sanding and assembly.

I sand on a 6×48 belt sander up to P180-grit, paying close attention to avoid putting too much pressure in one spot. I finish sanding by hand or with an orbital pad sander to P320-grit.

Then I apply a heavy coat of Danish oil. It often helps to rag on a second coat of oil on the outside. Most of the boxes I make are small enough to hold in my hand while being oiled. With a larger box, I oil the insides and sides, then flip it over onto sticks to oil the bottom.

From Fine Woodworking #185

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bumblechutes Bee’Nooba Wax

Odie's Oil

Log in or create an account to post a comment.

Sign up Log in